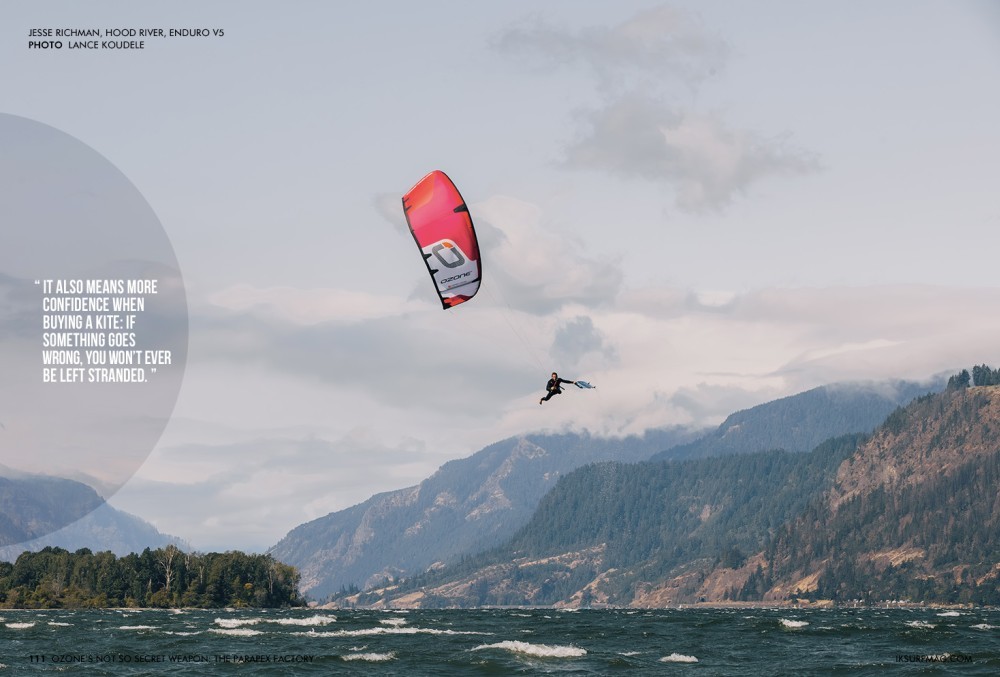

Ozone’s Not So Secret Weapon: The Parapex Factory

Issue 111 / Wed 25th Jun, 2025

In this feature, Rou Chater takes a behind-the-scenes look at how having full control over design, manufacturing, and innovation has allowed Ozone to build some of the most reliable, high-performance gear on the market. From custom orders to lifetime spares and sustainable practices, this is what happens when a brand puts riders and quality first. Find out more about Ozone’s Not So Secret Weapon: The Parapex Factory here.

Our sport is often defined by the products that come to market; new kites, boards, bars and foils all have their day in the limelight. Looking back, plenty of moments in time have defined the era and changed the sport in ways we couldn’t imagine. The rise of the bridled “bow” style kites in 2006, improvements to bars and safety systems, and iconic kites and boards have captured the imagination along the way.

One thing that is often overlooked is where and how these products that bring us so much joy are manufactured. We all bemoan the seemingly ever-increasing costs of our favourite toys, but do we ever look under the hood at what happens to bring them to us? For the most part, brands will outsource their production, often sharing factories with other brands. This might surprise you, but 90% of the world’s wetsuits, including all the brands you love, bar Rip Curl and a few boutique options, are all made in the same factory.

It’s the same with kites and boards. Cobra is a behemoth in the board manufacturing world, having near total market dominance. And there are plenty of brands that perhaps wouldn’t want to sit next to each other in a restaurant, but who rub shoulders sharing the same kite manufacturing facilities. The hard and fast fact is that all these factories require huge investment, not to mention a vast pool of skilled labour.

For most brands, this is impossible even to consider, especially when they first start out, but for one brand in our industry, it became a way to improve their equipment and stay ahead of the game. Ozone was founded in 1998 by David Pilkington, Mike Cavanagh and Rob Whittall, passionate paragliders who soon developed a love for kite sports. Ozone set out to create some of the best equipment for paragliders and kiters around the world. It wasn’t long before the team realised that if they wanted to set themselves apart, having total control of their production would be an absolute must.

The Factory

David Pilkington travelled to Vietnam in 2000 to set up a production facility. In 2001 the team's passion for kites was boosted by the energies and vision of Matt Taggart who joined Mike, David and Rob as a fellow founding partner of Ozone Kites LTD. Blood, sweat and devotion were poured in to push Ozone into the hearts and minds of kite shop owners and their customers. Meanwhile, behind the scenes in Vietnam, what had started out as 20 sewing machines in a single room, Parapex was evolving to become one of the world's most extensive production facilities for paraglider and watersports equipment. The site now spans an area equivalent to two football fields and employs over 1,000 people.

Parapex is more than just a factory; it’s a statement of intent from one of the world’s most popular brands. It represents total control over quality, innovation, and customer support in an industry where most brands are at the mercy of external supply chains.

For riders, this has real implications: cutting-edge products built to exacting standards, faster product evolution, exceptional spare parts availability, and gear you can count on year after year.

Running a factory is a massive logistical and financial undertaking; there are numerous factors to consider, from wages to energy supplies, not to mention the location of the factory within a global supply chain. You need to consider not just the raw materials coming in but also the finished products heading to customers. For Ozone, while the costs are substantial, the payoff is enormous, from prototyping and developing new products to creating unique production techniques that reduce waste and costs, not to mention being able to create new products quickly within their own timeframe.

This means there are no compromises. No “close enough” tolerances. No waiting for third-party suppliers to prioritise their orders. Every kite, wing, board, foil or harness that leaves Parapex does so only when it meets Ozone’s exacting standards. In our vast experience of testing Ozone products, we always feel that quality and attention to detail are evident when we unbox anything they send us. Hold up the stitching on an Ozone kite to a competitor and you’ll often see a marked difference in accuracy and workmanship.

Because Ozone owns Parapex, there’s no need to compromise on materials or processes due to supplier constraints, either. They choose the best fabrics, threads, and reinforcements because they can. And if a prototype reveals a new way to strengthen a seam or reduce drag, it can be implemented immediately without waiting for a third party to adapt.

For you as a rider, this translates to polished gear that works exceedingly well and comes with some of the best customer service backup you can imagine.

Kitesurfers know the details matter. Stitch patterns, panel tension, reinforcements, and valve placements affect performance, durability, and even safety. At Parapex, every kite is built by a team of highly skilled technicians, many of whom have years, if not decades, of experience. These aren’t underpaid workers on a production line, however. Ozone has invested in training, facilities, and a work culture emphasising pride and precision.

Even though over 1,000 people work there, it’s more of a family than a workforce. With out-of-hours social gatherings, from football matches to beach parties, Ozone really fosters an employee dynamic that should be applauded. Khanh is the Factory Manager, and a keen kitesurfer; he really fosters this family ethos; his daughter is now learning to kitesurf too, on an Ozone kite, of course!

Made Just For You

Perhaps one of Ozone’s most forward-thinking innovations is its manufacture-to-order system. This is highly unusual in the kitesurfing industry. While most brands forecast demand months in advance and produce large batches of gear that sit in warehouses, Ozone operates on a lean, responsive model. Kites are only manufactured when a customer or distributor places an order.

It’s no secret that the industry is in a total bind because of the oversupply caused by some brands thinking the gravy train wouldn’t ever stop after the COVID boom. There is a glut of gear still out there that has seen brands, distributors, and shops go under. It’s been a real blight on the industry for the last two years. However, Ozone can proudly say they weren’t part of it.

Their manufacture-to-order system is unique and has many benefits, but it also has some drawbacks. If you order a kite today, it should be with you within four to six weeks, which can be off-putting for some customers. While they have had no part in the overstock issue, they are still affected by it, with kites on 70% off discounts that make it hard to compete when you only ever sell at full retail.

That’s arguably where the downsides end, though, and if you are prepared to wait, and let’s face it, good things come to people who do, then you are in for a treat. Fortunately for Ozone, the unique offering from their lineup means a loyal customer base is always keen to get their hands on Ozone’s latest products.

From an eco perspective, this system reduces waste; there is no overstock, and they only produce what has already been sold and paid for. As a rider, there are benefits too; your gear holds its resale value, as there are no close-out deals or 50% off moments at the end of the season that would hammer your second-hand value. Ozone doesn’t do an annual overhaul colour change for the sake of it either, their vast range gets updated when it is good and ready, usually staying in current production for up to two years and sometimes longer.

They won’t ever release a new product unless they feel the benefits of the new design totally warrant it. This means there is no rush to meet a production deadline, which allows the designers to refine the gear to the pinnacle of performance. Again, this helps maintain your resale value for longer; your gear stays current rather than being tied to the industry’s annual ticking clock.

Of course, the other huge benefit of manufacturing to order is that you can choose the colours you want. We’ve all been there in the shop, wanting the red only to find that they only have black. With an Ozone order, you can pick from a standard set of production colours or select your own and easily build your unique colourway on their website. Check out the Custom Colour Chooser on every product page under the ‘Colours and Availability’ tab. This tool allows riders to personalise their kite’s colour scheme and provides real-time insight into factory stock levels and estimated lead times if a custom build is required.

More than this, though, Ozone offers a full custom design service. We’ve all seen Kai Lenny riding his Red Bull-branded gear; Ozone made that. Whatever you want on your kite, they can do it, and you won’t be waiting forever either; they are made in a similar time frame to the standard and custom colour options.

It’s a business model that requires confidence in your logistics and supply chain, which wouldn’t be feasible without owning the factory. Ozone makes it work, and the riders benefit directly from it.

Spare Parts? No Problem.

As equipment costs have gone up, many of us are keeping our quivers for longer. Ozone offers a comprehensive lifetime spares program, meaning you can obtain a bladder, valve, or any other part you might need to keep you on the water.

One of the biggest pain points in kitesurfing is what happens after your kite gets damaged. Need a replacement bladder for a five-year-old model? Good luck. A replacement valve for a discontinued kite? Maybe on eBay, if you’re lucky.

We often don’t talk about the ability to get spares in our industry, and perhaps we should. As we strive for a greener footprint, keeping kites running for longer is ever more prescient, especially when they are so damn good nowadays.

Because they control the manufacturing process, Ozone offers lifetime spare parts support. That means they can fabricate any part for any kite they’ve ever made. Bladders, valves, canopy panels, strut sections—whatever you need, the factory can produce it, often with the original materials and specifications.

This is an incredible advantage for riders who want to maintain their gear for the long haul, rather than treating it as disposable. It also means more confidence when buying a kite: if something goes wrong, you won’t ever be left stranded.

It’s a circular, sustainable approach to gear ownership that fits perfectly with the sport’s growing emphasis on responsibility and stewardship of the natural world we ride in. “Inspired by Nature” is, after all, one of the brand’s key mottos.

Faster Innovation, Better Performance

Owning your own factory doesn’t just help with quality and logistics; it accelerates innovation.

When Ozone’s design team develops a new idea, they can prototype it in-house, test it, refine it, and push it into production without waiting for external partners. This feedback loop is fast, efficient, and entirely within their control.

It also means they can be more experimental. Want to try a new bridle layout? A different Dacron configuration? A lighter bladder material? No problem. The designers can trial new ideas, designs, and materials and have the prototypes back with them within a week. More than this, though, the factory can look at how they will mass produce these developments right away, meaning a much faster route for the product to get into your hands.

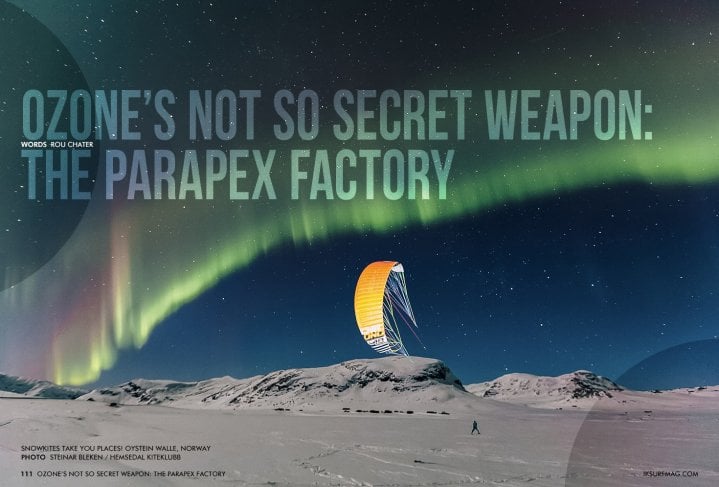

This agility is one reason why Ozone continues to produce high-performance kites that dominate across disciplines, from wave riding and freeride to race, hydrofoil, snowkiting, and paragliding, where they are also a dominant force.

Built by Riders, for Riders

There’s another intangible but essential benefit to owning your own factory: ethos.

Ozone’s team is made up of passionate riders, many of whom are deeply embedded in the sport. They understand what matters to kitesurfers because they are kitesurfers. And that passion filters through every part of the business—from design to manufacturing to customer service.

Parapex isn’t just a production facility. It’s an extension of that ethos: a place where rider-centric innovation is encouraged and built into the operation’s DNA.

Why It Matters to You

As a reader of IKSURFMAG, the chances are you know your gear. You know that when heading out in marginal wind, launching off a reef break, or boosting a huge mega loop, you want to be riding equipment you can trust.

Here’s what choosing Ozone gives you:

Reliability: Factory ownership means fewer failures, tighter tolerances, and more durable products.

Support: Lifetime spare parts mean you can repair, not replace, and stay on the water longer.

Performance: Faster innovation cycles mean you get the best designs, constantly refined and tested.

Sustainability: Less waste, less overproduction, and longer product lifespans mean a smaller footprint.

Transparency: You know who makes your gear, where, and how.

Ozone’s model stands out as something genuinely different. They’re not just building kites; they’re building a better way to support the sport and the riders who live for it.

Should You Care?

Not every rider will care about who owns the factory that makes their kite. But maybe they should.

When your kite flies more smoothly, lasts longer, and can be repaired years down the line, that’s not just luck. It’s the result of a deliberate choice to do things differently. Ozone has made that choice, and the result is a brand that prioritises quality, support, and sustainability in ways that few others can match.

So the next time you launch an Ozone kite, know this: it didn’t come off a generic production line. It came from Parapex, a factory built by riders, for riders, and it was made, quite literally, just for you.

Videos

By Rou Chater

Rou has been kiting since the sports inception and has been working as an editor and tester for magazines since 2004. He started IKSURFMAG with his brother in 2006 and has tested hundreds of different kites and travelled all over the world to kitesurf. He's a walking encyclopedia of all things kite and is just as passionate about the sport today as he was when he first started!