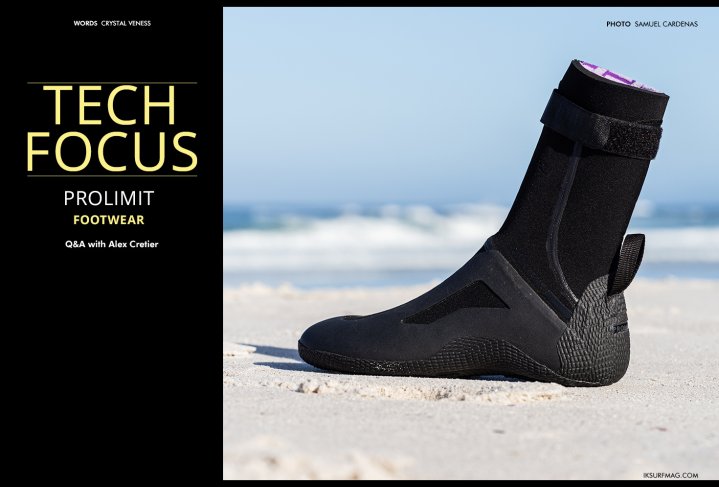

Tech Focus: Prolimit Footwear

Issue 96 / Thu 15th Dec, 2022

Winter is upon us in the northern hemisphere, and the new name of the game is keeping warm enough to stay out on the water longer! In this Tech Focus Q&A, we catch up with Alex Cretier, Director of Prolimit and Kubus Sports NL, to find out all about their footwear.

Alex, Prolimit has an extensive selection of neoprene for the feet with six key models and even more choices within, from different thicknesses to split or round toe options. Why is it so critical to have the right boot when you're kitesurfing?

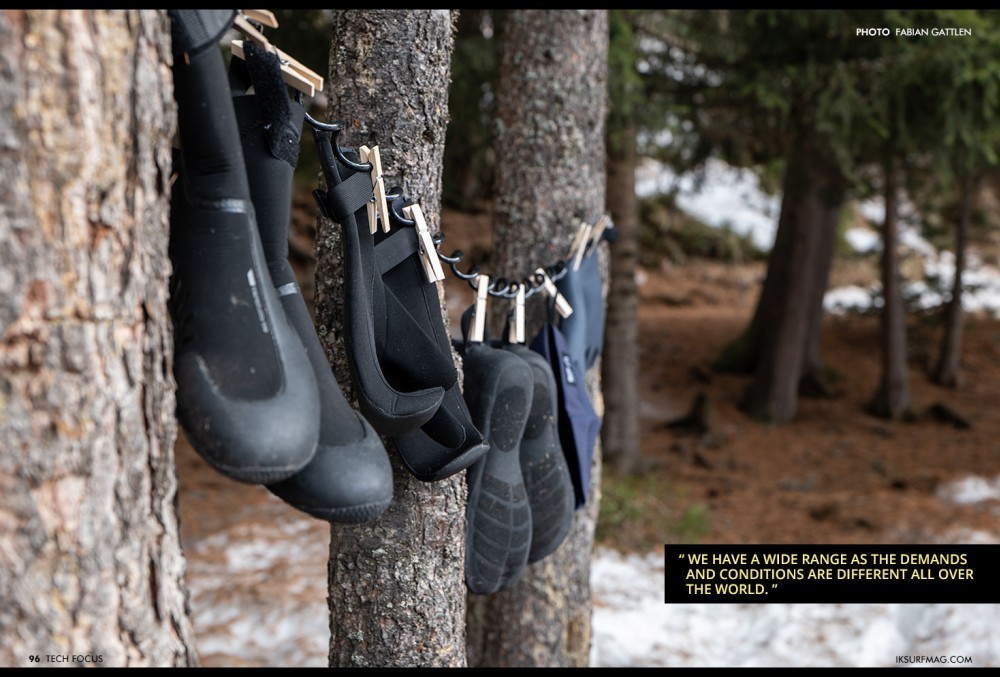

Prolimit is not just making neoprene footwear for kiting. We do this for a wide range of watersports, each with specific needs. Yes, we have a wide range as the demands and conditions are different all over the world. The right boot for kiting is the boot that best suits the conditions, whether that's a minimalist neoprene sock with sole reinforcement ranging up to a thick 6.5mm Polar boot. The Armoured boots are for areas with clamshells and the icy conditions in the Northern part of the world to the cold waters of the Atlantic Ocean in Cape Town.

There is a lot of technology that goes into neoprene footwear that we don't often talk about. So, what is OCL, and why is it important?

Prolimit is the only neoprene footwear producer using its own exclusive Lasts for its boots and shoes. OCL stands for Orthopaedic Controlled Lasts. To understand what it does, you have to know the production process. A neoprene sock is made, fitted on the Alloy Lasts, and then the rubber is applied and cured in an oven. This curing process determines the shape of the boot. Most of the Lasts out there are not made specifically for our kite and wind sports, where a dynamic stance and barefoot feeling are required. OCL ensures that at the arch, sole and also your Achilles tendon, the neoprene fits perfectly, and there is no air in your boot. As soon as you enter the water, the air disappears and sucks the water inside. If you look at an OCL boot, you will see that the sole is concave, the arch is lower, and the back of the boot is narrower at the Achilles. OCL connects, so there is no suction and a much warmer, better-fitting boot.

This is a feature that Prolimit has that its competitors do not - how much of a difference does this make for the user?

That's right. Our OCL are unique to Prolimit and a huge investment in something you don't experience until you use the product. The manufacturing process requires hundreds of Lasts, all made of aluminium (to withstand the curing process in the oven). You can imagine we are really talking about attention to detail here.

What is a DCL sole? What benefit does this offer the user?

DCL means Direct Contact Sole. When we make a boot, for example, a 6mm version, we use a thick neoprene for the top of the boot but a thinner neoprene for the sole itself, which, including the rubber layers, is not thicker than the top of the boot. This way, we create more direct contact with the board and provide that barefoot feeling. The Direct Contact Sole makes you feel connected to the board and not on a spongy layering of neoprene, rubber and linings.

Your HydroGen, Mercury, and Predator models are the top-of-the-range and warmest products in your selection. What materials are they using, and what features do they each offer?

There is a big difference between these three lines. On the Mercury split toe, we use Airflex 500+ together with TR. Thermal Rebound (TR) is the unique layering easiest to compare with a thermal blanket also in use in our Mercury, OxyGen and Vapor wetsuits. In this boot, we also use the unique X-Grip sole (a flocked rubber in a flex pattern) in combination with Zodiac Lining.

Our HydroGen model is a round-toe boot also using the Zodiac lining and X-Grip. Lastly, the Predator is a wide range with Armoured Soles (extra protection for sharp objects) to an easy step in boot. All are using one of our highest stretch neoprenes.

How do you secure the seams so they are both watertight and comfortable?

Most important on boots is that they fit perfectly and do not suck in water due to non fitting areas around your foot. All Boots are GBS, which means watertight seams which are triple glued and stitched, offering a watertight and durable seam. Some of the boots even use the FTM (Fluid Taping Method) seal as an additional reinforcement.

Prolimit has a strong sustainability policy, a topic that often comes up when talking about neoprene. What sustainability considerations are in place in the footwear line?

That is correct. Being the only brand with an FSC certification on our PF-2 wetsuit, we also care about this side of the range. On boots, we also use Limestone neoprene, water-based glues, recyclable packaging, and recycled carbon black and dope-dyed fabrics. We are continuously searching for even more environmentally friendly production methods.

Thanks, Alex, for taking the time to share more on the Prolimit Footwear line!

We are glad your magazine is giving extra attention to boots, an underestimated part of your equipment. We can imagine that our customers think a boot is just a boot, but there is more to it. The OCL Lasts are an important part of our developing process, and we at Prolimit consider focused product engineering and product-driven marketing as that's what makes us stand out. We've got you covered!

By IKSURFMAG