Intriguing Beings: Brainchild Production

Issue 96 / Thu 15th Dec, 2022

If you haven't gotten hooked on podcasts yet, you might be missing out on some of the most interesting industry news out there! In this article, Publisher Rou Chater recaps some of the highlights from his latest Intriguing Beings podcast featuring Ralf Grösel and exploring the future of sustainable production.

Traditionally the water sports industry has never been very eco-friendly. Using resins, foams, and exotic materials that can't be recycled and producing most goods in Asia when the main markets are Europe and the US... The carbon footprint alone is enough to make your eyes water. At least, we use the wind to put a smile on our faces, and we can, once we have it, use our equipment again and again and again. But, what if we could change the way our industry produces equipment?

It's a conundrum that has been on Ralf Grösel's mind for some time. If you haven't heard the name before, he is the designer for some of the most iconic kites in the sport. The Dice, Rebel, Vegas and Evo are all his creations, and he's been a designer at Duotone for many years. More than that, he's also set up production facilities in Asia and worked at the coalface when it comes to making the gear we love.

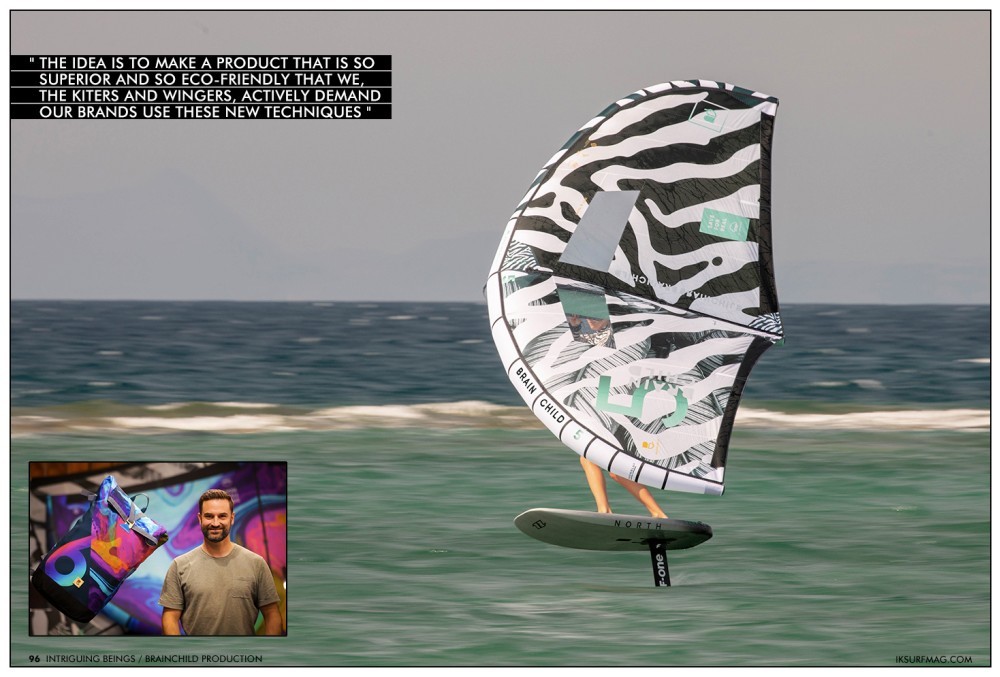

Ralf felt there had to be a better way to produce the equipment we love so much, so he came up with Brainchild Production. A new, truly sustainable production facility in North Macedonia, in the heart of Europe. It wasn't an idea Ralf stumbled upon overnight, it's the culmination of his life's work and patents he filed years ago, finally getting to a stage where they can come alive in his facility.

Starting at the top, the roof of the Brainchild Laboratory is covered in solar panels. Energy production is one of the highest costs in any factory, so using the sun to power all the machines and lights makes perfect sense. However, this is just the tip of the iceberg. Ralf dives so deep down the rabbit hole that it was almost hard to keep up as he took me on a tour of the factory.

All the material he uses is white. You read that correctly. The material comes from France and is recycled where possible - and white. Dying fabrics not only costs time and money, it uses a lot of water, a precious resource we all need. Using coloured fabrics creates waste, as brands don't want odd colours at the end of a run. So by using white fabric, he saves up to 6 times as much water as traditional dyed fabrics.

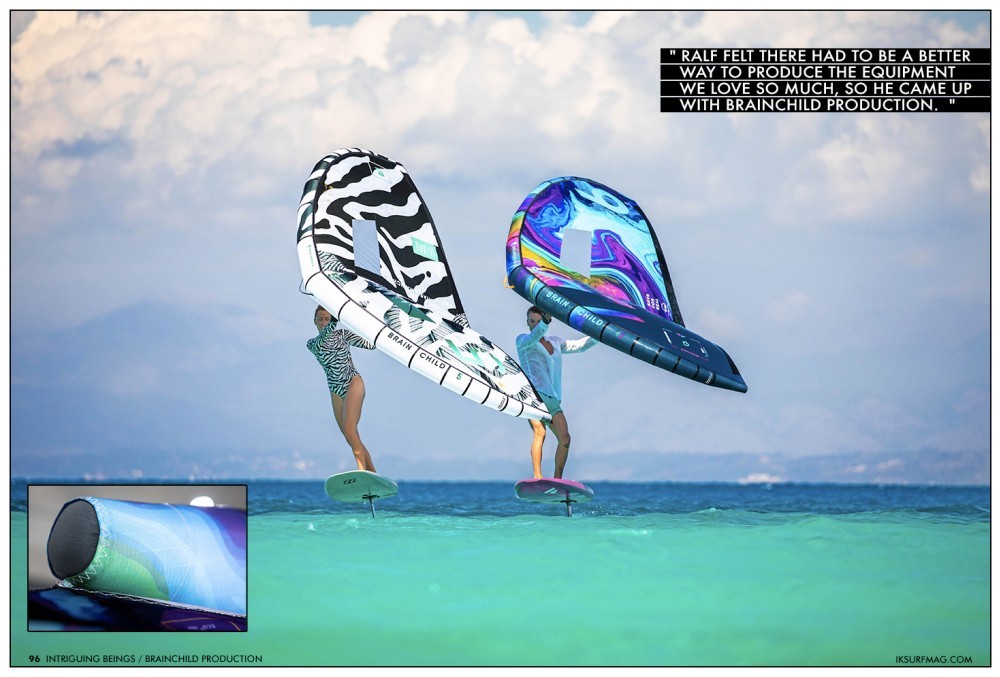

Of course, we don't want white kites, so he's spent the last 6 months developing an eco-printing solution that really is incredible. The detail is unbelievable. It's photo-quality printing on a massive scale that is going to completely transform the way our sport looks. The future is very bright indeed. Naturally, all the inks are eco, and the footprint of this technique is minuscule in comparison to screen printing, which is how graphics are traditionally put on our kites.

Alongside these new techniques, there is perhaps the jewel in the crown, dubbed the Proweld. Imagine a leading edge that has no stitching… All the segments of the leading edge on his kites and wings are welded, using a technique that Ralf has patented and developed himself. It creates a stiffer leading edge with better structural integrity while also saving weight and reducing the stress on the bladder inside. He's kept a very tidy leading edge closing seam, so repairs can still be made, but the weight saving is a huge benefit too.

Elsewhere where panels are stitched, Ralf is using recycled yarn from Germany. His goal is to keep the distance of travel for all the components as small as possible. Locally he is using moulds machined only a few miles away to inject with recycled plastic to create all the plastic parts of the equipment; think valves and tube clips, and you'll start to realise how much plastic is on a kite.

Taking things further again, he's looked at every individual part to reduce it to what is absolutely necessary, shaving millimetres off where he can to save on weight but also save on raw materials and wastage. It's truly groundbreaking stuff that goes into the smallest of details.

It goes without saying that Ralf is looking after the staff too. They have a huge kitchen and dining area that could easily be a high-end restaurant with a garden overlooking the mountains. Inside the factory, there are stunning images of local Macedonian scenes to create a sense of pride amongst the team. All the products are proudly stamped with the country's name.

Going another step further, he has even set up a local sewing school for anyone wanting to learn to sew. Ralf recognises he needs the best of the best to create the ultimate products and wants to train people up. The course is free, and you don't have to work for Ralf at the end of it. He says it's one of the ways he is giving back to the local community.

As far as technology is concerned, a lot of what Ralf does inside the factory is cutting-edge. He's building his own machines to create the products he wants, going as far as 3D printing components to create them. There is a whole section at the back of the factory dedicated to this purpose.

Having all of these amazing processes and being super sustainable isn't going to cut it if the product isn't good. I was fortunate enough to see some finished wings, and they are just in another class compared to what we have today. It's like Ralf is playing on a different planet while everyone else is still at the ballpark.

It's going to be a while before we see any Brainchild products come to the mass market - a year or so is a good estimate. And Brainchild isn't a new kite or wing brand hitting the market, either. Ralf is trying to make a brand and business out of the production process so that brands can partner with him to create their kites; think CORE or F-ONE manufactured by Brainchild. The idea is to make a product that is so superior and so eco-friendly that we, the kiters and wingers, actively demand our brands use these new techniques, making the world a better place for everyone.

I was blown away by my visit to North Macedonia. What Ralf and his team are doing is not only groundbreaking and, at last, truly sustainable, it's pretty mind-blowing too. Hopefully, this is the start of a movement towards a better way forwards and, indeed, a better product!

Want to know more? Click here to tune in to the Intriguing Beings podcast!

Videos

By IKSURFMAG