Tech Focus: The Airush Approach

Issue 92 / Thu 7th Apr, 2022

What does the development cycle of a new kite product look like? Clinton Filen, Airush Brand Director, takes us behind the scenes, giving us some insight on just how many people and how much time it takes to bring a new product to market. Find out more in this Q&A!

"By Innovators, For Innovators". Tell us a bit about the creative geniuses behind the scenes at Airush!

We are a group of designers and riders coming from different disciplines, with different backgrounds, each of these adding something unique to the mix. We are based in Cape Town, which also serves more as a hub, connecting point and primary test centre for the global team. Innovation is not only about creating the latest technology; it is also the broad desire to take a step forward in riding performance, hence our ethos.

It is clear that Airush wholly embodies its brand values; Do your distributors, shops, clients, and customers all share this appreciation for innovation?

We do our best to connect with the beginning of the chain and connect with people who are riding and experiencing the products. There are so many positive moments when you see how stoked people are on the gear. If you are authentically passionate about creating good products, the good dealers feel this and many of them will share their feedback and input, as they are the link to the customer and many of them are on the water themselves.

Where do the designers and testers find inspiration to add new technology and production methods to Airush products?

There is inspiration everywhere. You just need to be open to what the future looks like and start to create that today. Of course, we also draw constantly on feedback from riders, dealers and customers.

Is it essential for Airush team riders and testers to be creative and development focused?

Certain athletes are 100% focused on riding, although they will normally use this as a creative outlet. In this case, their feedback may be purely focused on what they need the product to do in order to help push their level, and this is a good development focus. Connecting this, are key riders who are also product testers who are more analytical in identifying weaknesses or key areas to focus on.

Do testers and team riders provide product feedback or suggestions to the designers? How does this collaboration work?

The primary product testers will connect with the broader team and the designer. For example, Alex Pastor is very focused on Freestyle development and will work closely with each designer across the board, bar and kite range. The same goes for Victor Hays on the Freeride products; we will generally have a key tester in each category. That being said, our design team always encourage product feedback from all of our riders; after all, they are typically trying new things and pushing the limitations of the products.

Using the Session as an example, the current version was released in July 2020. When it comes time to develop the next version, how does the team identify areas of improvement?

The team will share their long-term feedback on the performance of the kites over extended use. We will also receive feedback from customers during demo events, tests and even groups of friends and customers who might reach out to us.

Wherever possible, we will be working on longer-term ideas in materials, constructions and shapes and translate these into new products.

Whether it's new materials, new stitching patterns, new profiles, or new bridle layups, how does the idea for a change get implemented and tested?

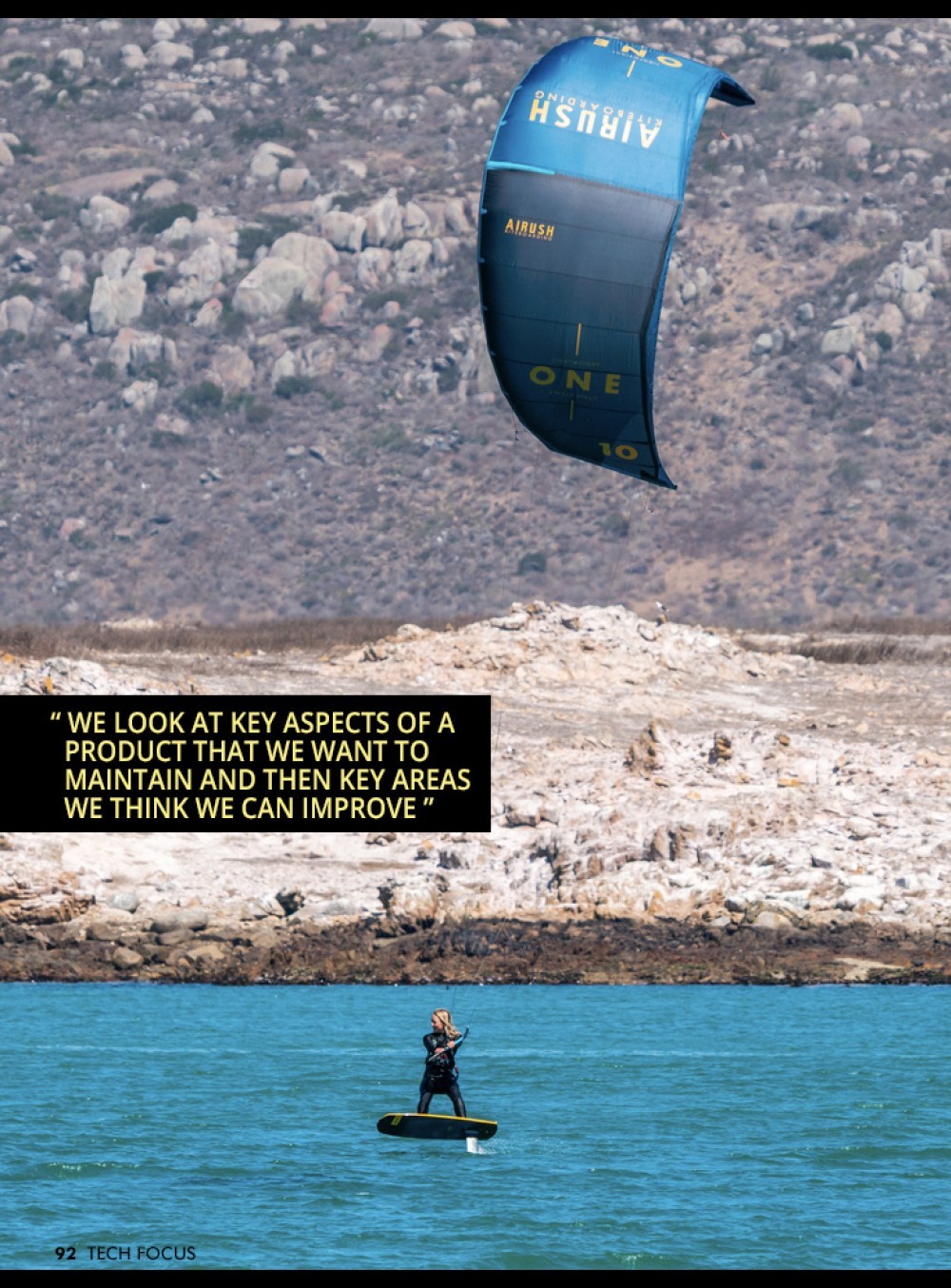

We are generally chasing key outcomes in each product, and there is a brief that consolidates all of the input. If you simplify it, we look at key aspects of a product that we want to maintain and then key areas we think we can improve, and we chase those. The challenge is often to improve one area without undermining the strengths of a product.

Is it often that, after making a concept into reality, it fails? How do you bounce back from an idea that doesn't work?

Real innovation is difficult, so you need to be conditioned to accept failure as part of learning, and this is a part of the culture we try to build in the company. If you are surrounded by people who are constantly trying new things and dealing with that reality, that is critical to innovation.

How long is the process from the first concept to testing to production to release?

That depends on many things, including the complexity of the project, the performance requirements, manufacturing process and the type of product. A new board might take a year, while a new kite material could take up to five years.

As we have a philosophy of no planned obsolescence (we replace products once we have a clear improvement), it means many products will be in an ongoing development cycle and only be replaced once we have made a clear step forward.

What is the most exciting innovation coming up - that you're allowed to talk about?!

Come Spring, we will launch a new material that we have been working on. We have heard some industry chatter and have had a few questions on it already, but we will tell you this, it's going to be big!

It is hard to highlight one thing, but right now, we have been enjoying an incredible season, with the standout products being the new Switch and Lithium. We put a huge amount of energy into the Freeride category for the season, and it is great to see the response.

By Crystal Veness

Editor at IKSURFMAG, Crystal Veness hails from Canada but is based in South Africa. When she isn't busy kitesurfing or reporting on the latest industry news for the mag, she is kicking back somewhere at a windy kite beach or working on creative media projects.