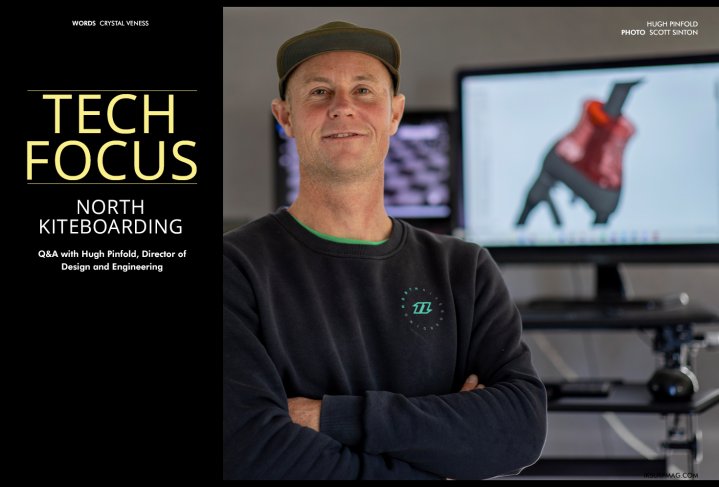

Tech Focus: Q&A with Hugh Pinfold, North Kiteboarding

Issue 90 / Tue 7th Dec, 2021

North Kiteboarding's Hugh Pinfold fills us in on what's new at North, how he got his start in product design, and what it takes to work at a leading brand! Read the interview exclusively at IKSURFMAG!

Thanks for chatting with us about what it's like to work on the design team at North! First, what is your job description, and what does that entail?

My job description is Director of Design and Engineering. This involves being part of all stages of product development, from concept, detailed product design, and graphic design to industrialisation.

What does being the head of a department mean for you? Are you overseeing all product design at North?

It means whenever there is wind, I have to be out testing - haha, I wish. But honestly, I am part of a tight product development team that oversee all North products. This doesn't mean I lead all products, but with so many years of industry experience between us all, it often means any potential issues can be weeded out early in a product's inception.

Let's talk about the North 2022 collection. What are the key design and brand goals for North going into 2022?

Our key design goals are always to offer beautifully functional, intuitive products that just work when you need them. We strive to use the best material possible for any given product to excel in its intended function. We work hard to really strip our products back to the bare necessities, giving you pure lightweight performance. At North, we believe that less can really be more.

What 2022 product are you most excited to share?

Our Navigator control system has had some great incremental improvements to make it even easier and safer to use. The Flex bindings also have improved fit and aesthetics. The Comp surfboard's new Dynalite construction makes for a very lightweight yet strong and responsive weapon.

One standout product for me is the new Sonar HA1250 wing; I just love the speed, and pumpability and all-round intuitive feel of this wing in all different foiling disciplines. I've been adding a -1.5 degree shim to the stabiliser and am stoked to be using the same full carbon setup for prone foiling, kite foiling and wing foiling. I've been having a stack of fun on the Nova wind wing as well, so it's hard to choose only one product - I'm fizzing on them all!

Quick releases seem to be your area of expertise! Can you tell us a bit about how the quick release has been the launchpad to your design career in the kiteboarding industry?

I trained as a Mechanical Design Engineer, so I was naturally attracted to what improvements could be made to the quick release (QR) to make kitesurfing even safer. I've worked on various QR devices for Ozone, Cabrinha and North over the past 15 years. After you've improved a QR, you also start looking sideways at the rest of the control system, which leads to harness hooks, shell harnesses, bindings, kite inflation systems, etc. I actively enjoy all disciplines of kite sports, so I inevitably enjoy the challenge of designing improved systems using new technologies and often out of the box thinking.

For those young kiters out there that are aspiring to work in design in the kite industry, what advice can you share from your own experience?

Just get amongst the industry in any capacity possible. Offer your time and positive energy for free for a start at a local kite shop, do some instructing or try interning if you're lucky enough to have a manufacturer nearby.

I moved down to the South Island in New Zealand and worked a few weeks for free for an early kitesurfing brand called Underground Kiteboarding. This was my springboard to meeting other amazing people in the industry in all different positions.

There is learning in whatever you do if you stay open-minded and inquisitive. Life's short; work hard, play hard.

The North Navigator Control System is an outstanding product. What inspired the original design?

We were lucky to come to market a little later, which enabled us to critique all other control systems already on the market. This process allowed us to really focus on what functionality was most important for the Navigator to include.

The super-simple intuitive single click-in loading of the Quick Release was something I've dreamed of bringing to market for years, so this was a must to work hard on to develop.

I was conscious that more and more kite harness hook options were coming onto the market at the time, which led to us wanting to offer an easy toolless option to trade out your harness loop depending on what discipline you wanted to do any given day. I am still stoked with both the safety and simplicity of the Toolless Interloop system.

Safety is critical when it comes to kiting control systems. What have you and the North team done to ensure you are producing a failsafe product?

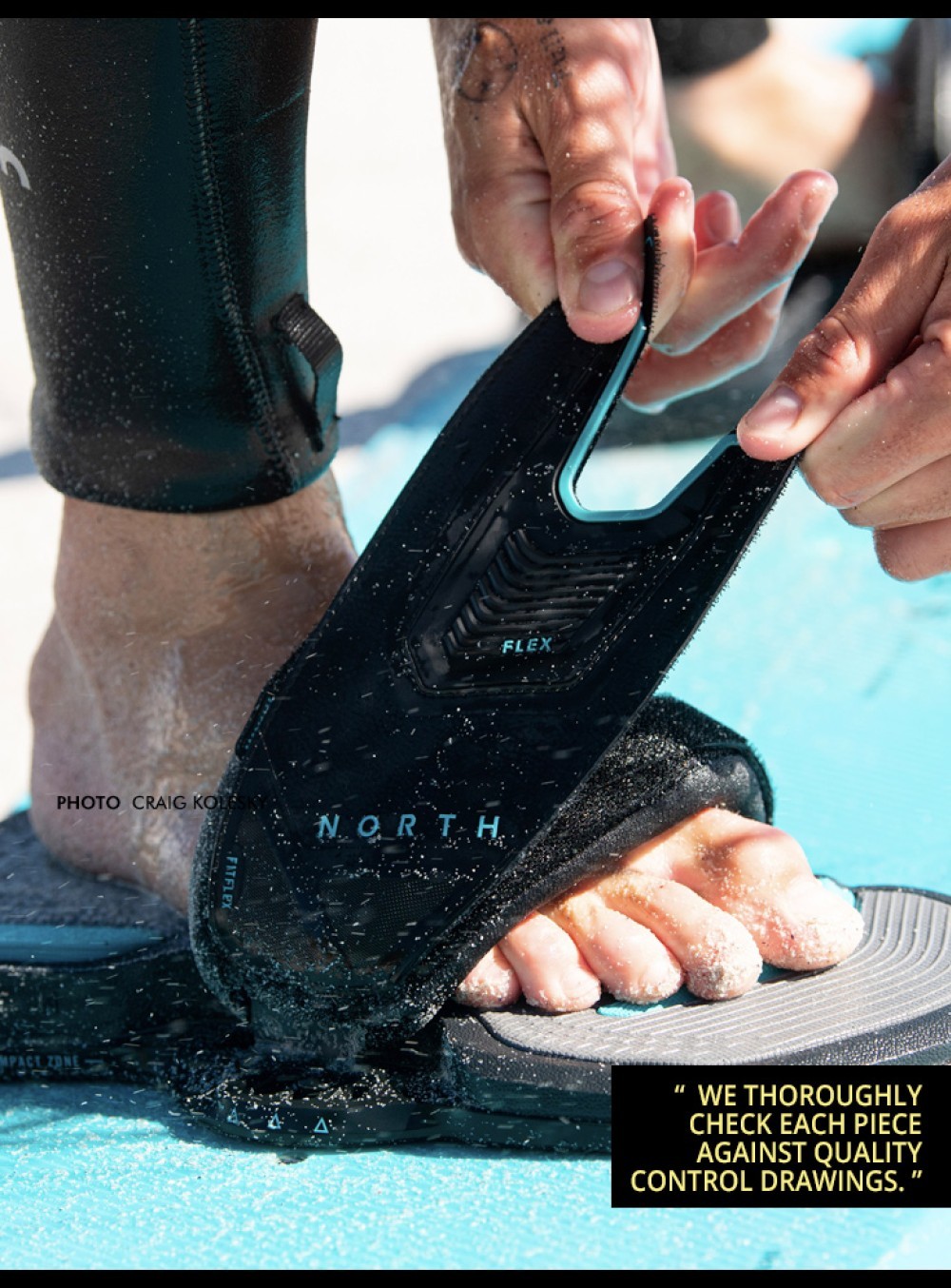

We have rigorous testing systems throughout the design process of a product and quality control processes during manufacturing of individual parts and assembly of all North products.

So firstly, before a product is signed off for production, we have a test team that records a minimum number of hours in varying conditions noting any areas of concern. During the prototyping process, we undergo UV testing, heat and frozen testing. This is often followed by tensile load testing and saline testing for corrosion (mainly on metal parts), amongst many other tests.

Once parts are ready off production tooling, we thoroughly check each piece against quality control drawings. We then implement further lab and on-water testing.

During production assembly, we take random parts and break-test them from different batches to ensure they are up to our specified standards. We also have inline quality control checkers in all factories and an independent Quality Control inspector checking final goods before they are packaged and ready for market.

Looking at the greater kite industry, do you think improvements towards safety have been made across the board?

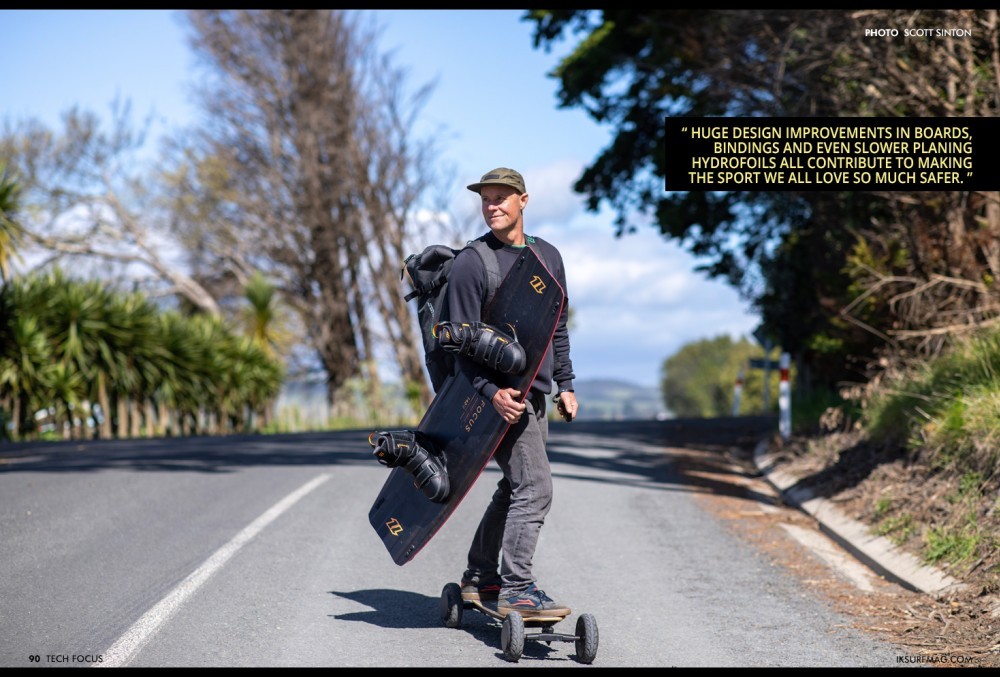

Most definitely; Kitesurfing is much safer than it was in the early days. Most kites depower by about 80% these days just by letting the bar go. You then have the option to let your quick-release go, which will 100% depower the kite. The mechanism must adhere to strict ISO standards in which the release must activate in under 0.5 seconds, in action away from the body with very little hand force in all conditions. Huge design improvements in boards, bindings and even slower planing hydrofoils all contribute to making the sport we all love so much safer.

What do you think we, as kiters, or more generally, as an industry, can do better to improve safety?

I think there needs to be a lot more focus on kiters checking for any wear or damage to their equipment and designers working on easy to replace parts that may wear over time. All companies should work to produce easy manuals or instructional videos to compliment this.

We would all love our equipment to last for as long as possible, but with the high loads that products are subjected to in some of the harshest saltwater and sandy conditions, long term wear is inevitable.

How does a connection with nature and the elements play a part in your work with North? And your life outside of work?

Being immersed in nature regularly is a must for me. It's my meditation. Pushing the limits of extreme sports performed in nature requires complete focus, taking you away from the often-minor problems in life. It always amazes me the clarity you get after a good adrenaline-pumping session. Some of my best solutions and designs seem to come whilst on the water or soon after. So, in this sense, my passion for the sport and work fuse together when in the elements.

Videos

By Crystal Veness

Editor at IKSURFMAG, Crystal Veness hails from Canada but is based in South Africa. When she isn't busy kitesurfing or reporting on the latest industry news for the mag, she is kicking back somewhere at a windy kite beach or working on creative media projects.