Tech Focus: Duotone Juice D/LAB

Issue 89 / Tue 5th Oct, 2021

Known as the apex predator of light wind kites, the Juice D/LAB is an exciting new addition to the Duotone lineup. We're going behind the design with Duotone's Ralf Grösel in this exclusive Tech Focus interview!

What is D/LAB? Is the future of kiteboarding design in the hands of the Duotone D/LAB team?

D/LAB stands for Duotone Laboratory. At D/LAB, we combine the latest materials with production technology. We aim to create the products of the future and to set new benchmarks within the industry.

What is your background, and how did you find yourself on the design team at Duotone?

Before entering the kite industry, I worked as a paragliding test pilot and designed paragliders. I've been in the kite industry since 2000 when I cofounded FLYSURFER.

In 2005, I began working at Boards & More. The first tube kite I was involved with was the Evo. Since then, I have been working in kite design and everything else that goes into the kite; materials, production technologies, and everything required to put the kite together. Currently, I'm designing the Duotone Evo/Evo SLS, Dice/Dice SLS, Juice/Juice D/LAB, and Vegas.

What was the design goal for the Juice D/LAB?

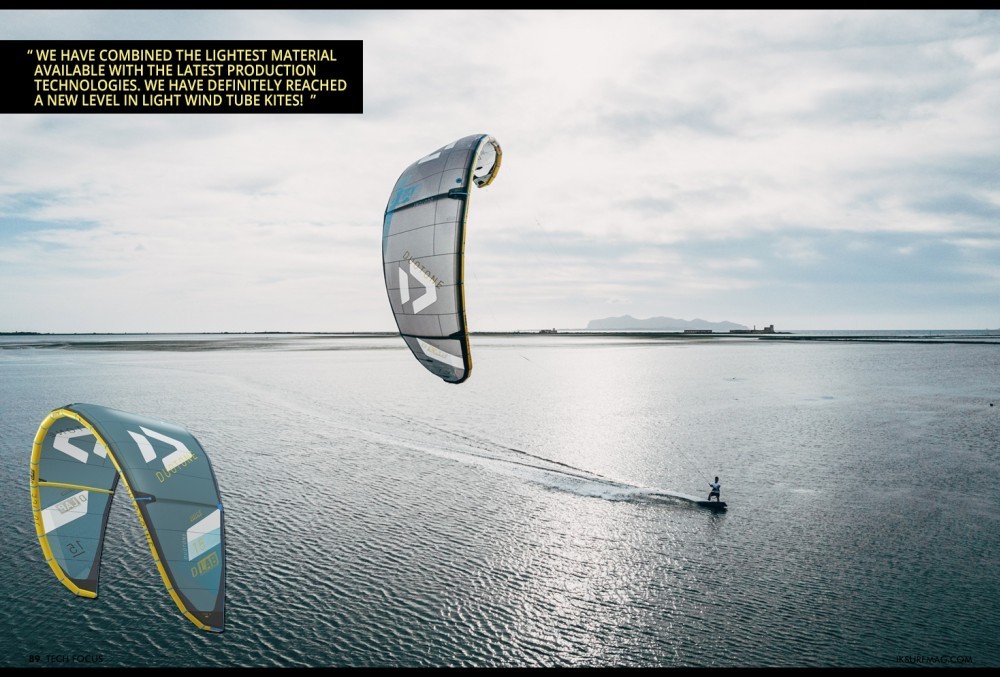

It was quite simple: Create the ultimate light wind kite. With the standard Juice, we had already set the benchmark for light wind tube kites. Over the last two years, we have decreased the weight by over 28%. Now, with the Juice D/LAB, we have combined the lightest material available with the latest production technologies. We have definitely reached a new level in light wind tube kites!

The kite is available in 13m and 15m, although these kites are not designed for the same purpose. What type of kiter should consider each size?

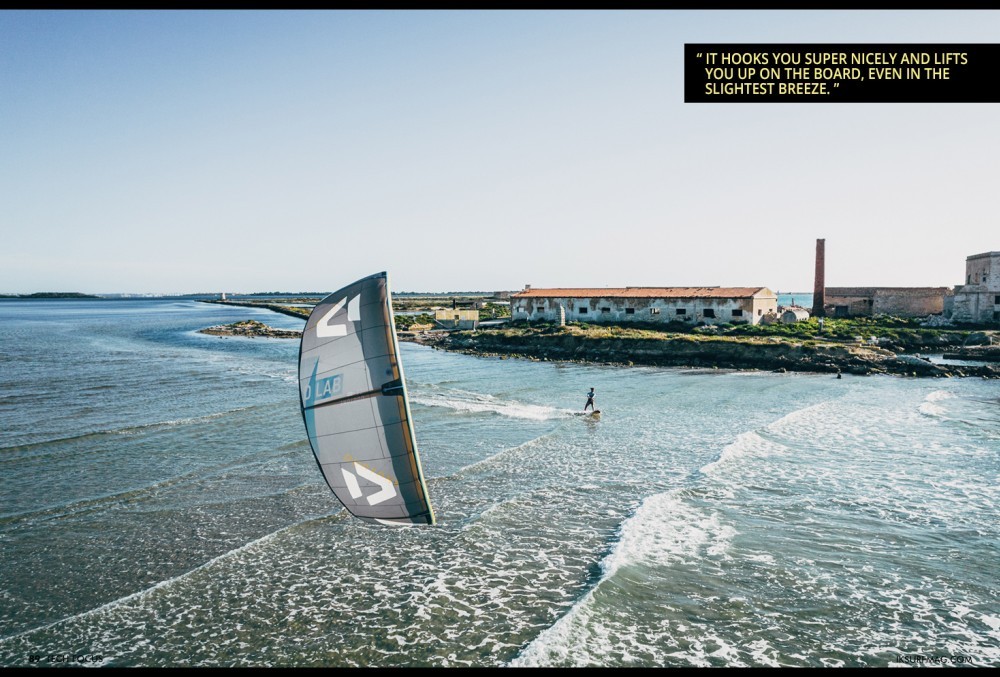

We designed two different kites to meet different needs. The 13-metre version is dedicated to foiling. There is no need to have anything bigger because it is so powerful. When you loop the kite down, it creates a lot of speed when it flies back up through the turn due to its light weight. It hooks you super nicely and lifts you up on the board, even in the slightest breeze.

The 15-metre is much more grunty in comparison to the 13. It's made to perform on a twin tip, particularly a big twin tip. If you want to go kiting in 7 knots of wind, you should have a big board, like a 165-centimetre board, to keep you going. The 15 is the ultimate lightweight kite for twin tip riding.

Can it truly fly in 4 knots of wind? How skilled of a kiter do you need to be?

Yes, it can. An 80kg rider using something like a Spirit Carve 950 foil combined with a board that has a little bit of volume can get going in 4 knots. It's not just the marketing blah blah; it is absolutely possible and quite easy to achieve.

Of course, it requires a certain skill level. You have to understand how to fly the kite in extremely light conditions. Once you get the technique right, everything that follows is just sensational. It's a real eye-opener because, in such little wind, you barely have any ripples on the water. Kiting on a mirror is a fantastic sensation.

Can you take us through the project timeline for the Juice D/LAB? How did this project come about?

The Juice D/LAB project took off after I made the first concept kite three years ago called the ultra-lightweight kite. It was a kite made entirely out of non-commercial materials. We used the lightest materials available today and developed new construction methods to manufacture and implement these superlight materials without breaking them.

The first kite was a 13-metre and weighed less than 2kg. It was incredible to see what was technically possible, and this was the kite I took out and was able to get going in 3-4 knots of wind. It was such a successful experiment that, from then onwards, we have really tried to push our light wind construction further and further.

What materials are used in the Juice D/LAB? How do these differ from the original Juice?

The Juice D/LAB features the Aluula material, which is currently the lightest material available on the market at around 80g per square metre. In comparison, the Penta TX, which is also a really light material, is around 130g.

The original Juice uses a DLE 140, which is around 140g. In the past, we used material that weighed 160g per square metre. So, you can see the difference between the normal Dacron at 160g and the Aluula at 80g has resulted in a 50% weight reduction, which is a huge benefit.

Working with new materials has got to be a big risk. What steps are required to ensure that the material is lighter while still durable and performing at a high level?

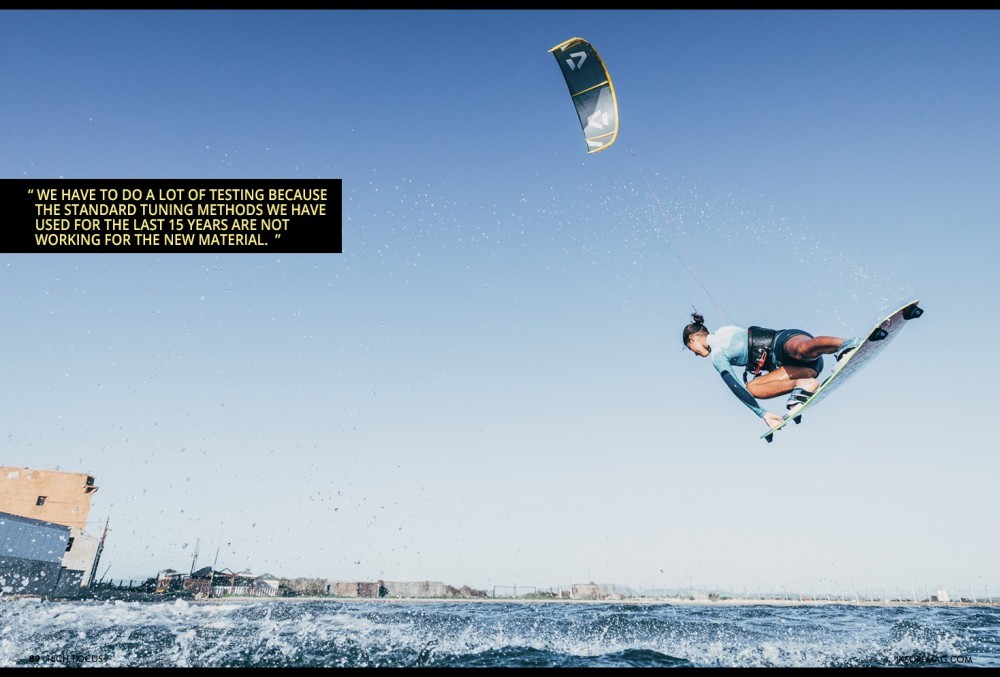

We have to do a lot of testing because the standard tuning methods we have used for the last 15 years are not working for the new material. It is not a woven; it is a classical laminate. We had to figure out what had to be changed, what kind of material combinations we have to use, and what reinforcements we need to add to the kite to ensure that the durability is still there. Again, it's testing, testing, testing.

We put 30 kites into the schools, equipped team riders and I was constantly riding the kite and putting a lot of flight hours into this construction to check which areas could have problems. It took us over a year to figure out all the negative aspects and then solving them, it was quite a long challenge!

Will the standard Juice be phased out of the Duotone range favouring the Juice D/LAB, or will these two products exist side by side?

There is a considerable price difference between the standard Juice and the Juice D/LAB because the Aluula material is literally ten times more expensive than the standard material. We will definitely continue with the Juice; it's a superb all-around kite for everyone who wants to get on the water early when the wind is light. It's also ideal for schools that are teaching on light wind days.

The Juice D/LAB is the extreme; It is a benchmark kite, something expensive, but also something kind of edgy because you need the skill set to fly the kite in almost no wind. Overall, it is a kite that allows you to ride every single day with only a little breeze. In the classical sea breeze conditions, when you go to the beach, and you have the feeling, "Oh my god, it's not going to be enough!" you will be able to go kiting with the Juice D/LAB. Even in only seven knots of onshore wind, it's enough, especially on a foil board.

Of course, it is a decision that is up to the customer; are you willing to invest this kind of money in allowing yourself to hit the water whenever possible?

Now that the Juice D/LAB is out the door, what is the Duotone D/LAB team working on at the moment? Can you let us in on any of these top-secret projects?

We are constantly working on developing new materials and construction technologies to push the sport further. Unfortunately, I'm not able to tell you in which direction. The Juice D/LAB and the Aluula material are not the ends of the line; It's more or less the beginning, and I think an entirely new set of material will lead us to some really interesting products in the future.

Thanks for taking the time, Ralf!

Videos

By Crystal Veness

Editor at IKSURFMAG, Crystal Veness hails from Canada but is based in South Africa. When she isn't busy kitesurfing or reporting on the latest industry news for the mag, she is kicking back somewhere at a windy kite beach or working on creative media projects.