Tech Focus - Lieuwe

Issue 80 / Thu 16th Apr, 2020

A new feature, looking at brands making a difference to our sessions with advances in technology. Lieuwe recently partnered with Teijin, famous for our kites canopy materials to work on a new fabric laminate for boards!

Lieuwe launched just over ten years ago, what was the thinking behind setting up the brand at that time?

Yes, we've been making boards for a while now! Our first board was created ten years ago, and we launched the brand in 2013. To give you the full story behind the brand, I need to introduce you to the founder himself, 'Lieuwe' Florian van Rije. Kiteboarding to Lieuwe is the route to freedom, but what do you do if your board doesn't feel right? Simple. You take it apart and build a better one!

Ever since Lieuwe was a kid, he had always been a creator, a natural-born shaper. When he started building boards, he quickly gained confidence from the feedback and recognition he was receiving. His thoughts seem 'a little' chaotic at times, but he works with great precision. Lieuwe also enjoys sharing passion, not only the boards but the ideas behind them and the building process itself. He encourages people to test the boards and then adjust the boards according to their preferences.

What was the factory-like when you first started, and what is it like now, has the process changed at all?

When we first started, the factory was 2x3m². It was a shed in the garden in Lieuwe’s house in Utrecht. Later on, he moved to the coast in Scheveningen, The Hague, where he continued working on his boards in a small workshop. At that time, board building was a just a hobby for Lieuwe and everything was done by hand.

In 2013, we moved to another place in The Hague, where we rented a basement which was about 1.80m high, and without any windows! However, it did have enough space to install our own built CNC machine, board press and plotting machine. That was the year we launched the brand and started selling our boards through shops all over the Netherlands.

We still had our regular jobs on the side at this point, and we worked shifts building boards to keep production going. In 2015, we decided it was time to quit our other jobs and focus mainly on Lieuwe Boards. We changed the business entity of Lieuwe and opened our first real 300m² factory by 2015.

Lieuwe could finally focus mainly on his passion, mechanical engineering, and to build the best boards on the market. Our machines were the biggest challenge we faced, and every cent that was earned was reinvested into the company so we could have better machines, to build better boards; and here we are today. All the machines we are using are made by the same hands that built the first Lieuwe board ten years ago, only bigger and better...

Initially, you were making custom boards, but now you have lots of off the shelf production models available, can a customer still get a full customised board from you?

Correct, in the early days all the boards were made to order, but as the brand expanded, the demand also grew. We had to make a decision; are we going to build production boards or not? We never believed in having production boards as we didn't want to become ‘just another brand on the market’. We decided to go ahead with a limited amount of production boards, available to shops without an excessive amount of stock. This way, we believed, we could maintain our philosophy.

Sustainability is a big issue these days; your boards have a very natural wooden look, how are you working to lessen the impact on the environment through the manufacturing process?

When we talk about the impact on the environment, it goes much further than the manufacturing process only. The supply chain has a huge impact on our carbon footprint, and we try to minimise this as much as possible by sourcing our raw materials locally, instead of choosing cheaper options from abroad.

We were in collaboration with Ruben Lenten for 2 years since 2017, and that opened doors to becoming a greener company. Ruben is the ambassador for Sustainable Surf and guided us in the right direction. We met with Michael Stewart from Sustainable Surf and got to learn about what they do. They run an excellent program called #Wastewaters, where they focus on helping companies reduce, reuse and recycle their materials. So that's one thing that we're we're doing at Lieuwe as well to make sure we create the minimal amount of waste and that it is handled respectably. Besides that, we choose materials that are less harsh on the environment; wood from a sustainable plantation and eco-friendly resin and paint. All these little bits will hopefully help in the long run and inspire other companies to think similar.

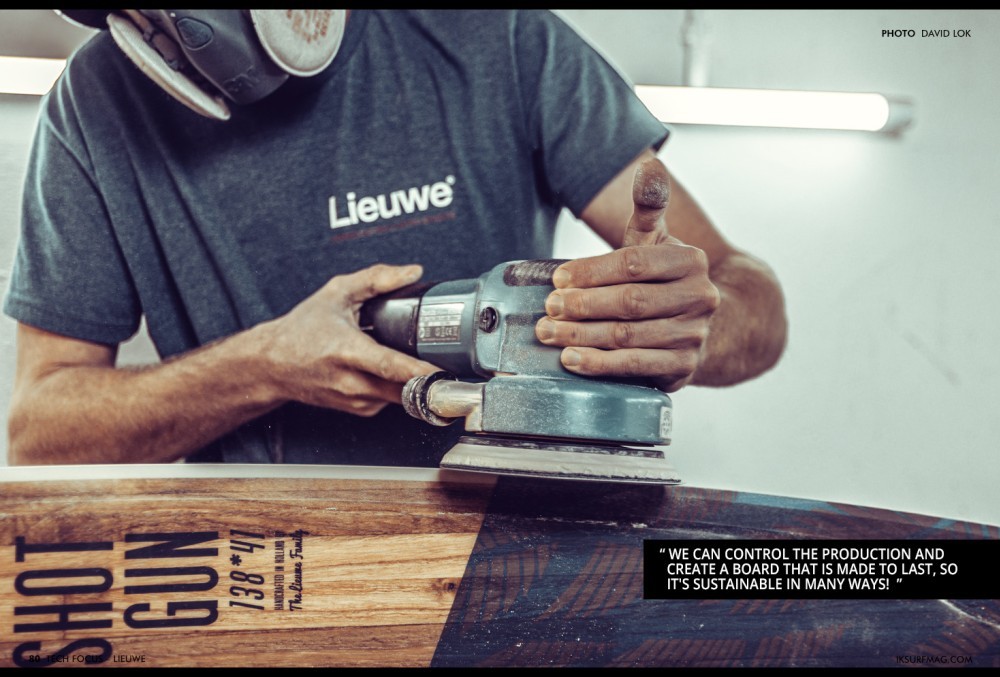

We have all our products in house to maintain the quality of the boards, due to the transparency of the boards, there is no room for imperfection; making the boards very hard to copy in mass production. We can control the production and create a board that is made to last, so it's sustainable in many ways! Additionally, we build a limited amount based on demand instead of huge stocks, not knowing what's going to happen on the market every season.

A new collaboration started with materials manufacturer Teijin recently, usually they are more famous for the canopy material in kites, what are they doing for board manufacturers?

Teijin Aramid, based in the Netherlands, is a composite company that produces impressive performance fibre materials, that offers unique characteristics that use daily. They approached us to test their materials and to create and develop a new board that offers new technologies and features that the current boards that are on the market don't have.

How does this new material change the way you are constructing the boards?

It does not change a lot in the way we build our boards; it 'sits just another layer that we add in the production. The biggest difference is that we need to cut the Twaron® with special scissors, as the material is extremely tough.

What are the performance benefits of Twaron?

We developed it with our team rider Roderick Pijls, and this is what he noticed in term of the performance benefits:

“The best benefits I get from processing their materials in my board is controlled stiffness, durability and shock & vibration absorbent. The material we process in my Oceana is called Twaron®. This is a performance composite fibre that, thanks to the perfect right-angles, enhances the stiffness of the board. The second benefit of this is that it has the same unbreakable construction as carbon fibres, so the board gets another unbreakable boost. But, for me, the most positive benefit is the shock absorbing factor. The best way to explain this is to give you an example; if you play tennis and you hit the ball with a loose grip, you'll feel the racket vibrating. While if you hit the ball with a firm grip, it doesn't vibrate at all. This also happens with processing Twaron® in my Oceana board. There are fewer vibrating impulses coming from the board that gives a smoother ride in all kind of conditions. It feels softer on the knees and joints.” - Roderick Pijls

Many brands use carbon and now materials like Textreme Innegra, what's the difference between all these high-end materials and which one is best?

All materials have their unique characteristics, but we tend to market them, making them seems better, which they simply aren’t! The way you should look at it is that some riders have specific needs, and for these riders, we have the answer by using different fibres to existing models which makes them more or less stiff, lighter, stronger, you name it…

Are we going to see further developments in board construction, what's the Holy Grail you are trying to achieve?

We will keep working on development with Teijin shortly and push the brand further as we enjoy being part of this development.

When a customer is choosing a board, what is the most important factor?

That they feel comfortable with the decision made!

How much difference does a good board make to a rider’s session?

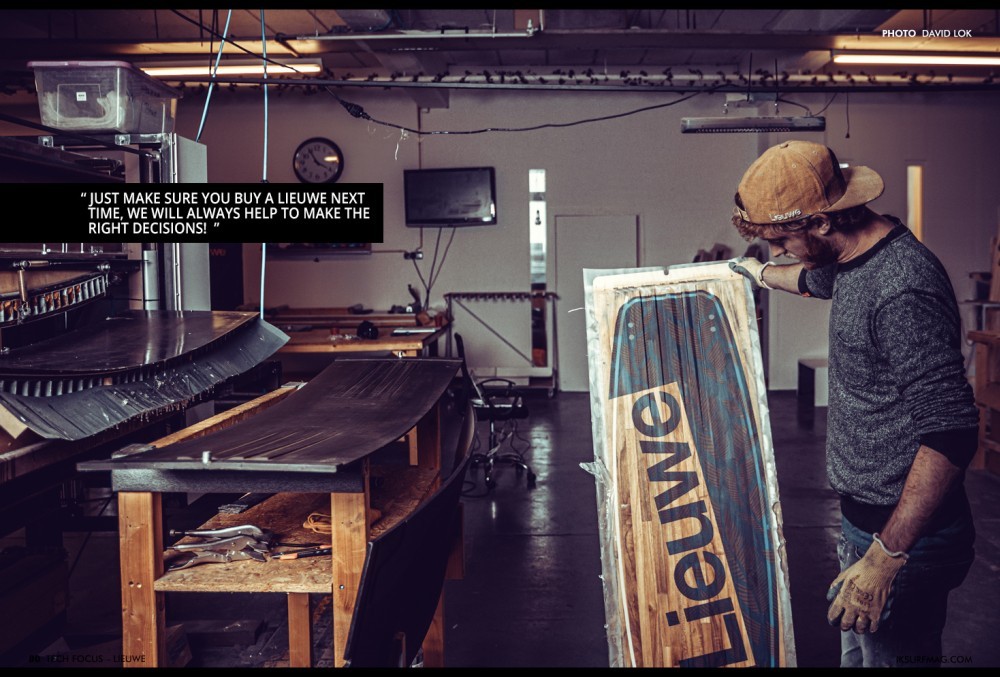

When you just start kiteboarding, it doesn't matter, you just want to go back and forth, but after a few months, you want something better, faster and you will take whatever that guy recommended in that shop you visited, without knowing you have been riding the wrong gear for years.

I can share a numerous of stories of riders who have been out for many years with the wrong board (type and size) and went out with the right gear, coming back to shore and say: WTF… what have I been doing all these years? Just make sure you buy a Lieuwe next time, we will always help to make the right decisions!

Thanks for taking the time!

Videos

By Rou Chater

Rou has been kiting since the sports inception and has been working as an editor and tester for magazines since 2004. He started IKSURFMAG with his brother in 2006 and has tested hundreds of different kites and travelled all over the world to kitesurf. He's a walking encyclopedia of all things kite and is just as passionate about the sport today as he was when he first started!