Industry Focus: Twins!

Issue 68 / Tue 10th Apr, 2018

A new feature looking at the science behind the sport, this issue we shine the spotlight on the humble twin tip, are they more than just planks of wood? Find out right here in our Industry Spotlight feature on the humble twin tip!

Twin Tips, are they more than just an expensive plank of wood?

In a new series looking at the science behind the sport and the industry, we take an in-depth look at the humble twin tip. For many of you it is where your journey started, overshadowed in recent years by surfboards, race boards and now hydrofoils, the humble twin is still the go-to craft for most riders. When it comes to bang for your buck, you can’t beat a decent twin tip on a windy day!

You’ve seen the videos floating around YouTube with kiters trying to ride on just about anything. Do these videos get you thinking about what exactly you’re paying for when you throw down your hard earned cash for a new deck? What’s that money going toward, and what should you be looking for when you’re shopping?

In this article, we look at boards that have a symmetrical outline and can be ridden in either direction, affectionately known as twin tips. The majority of kiteboarders get their very first rides on a twin tip. After those first few rides, the world of kiteboarding opens up. Some riders, especially those who are interested in freestyle and big air, stick with twin tips while many others explore surfboards, foil boards and other types of craft.

Does it matter what’s underneath your feet? In short, yes and I think that any kiter will agree. Different boards provide wildly different experiences for riders. Sure, there are kiters doing unhooked freestyle on foil boards and racing on twin tips, but to max out the potential in any given discipline, riders want gear that is tailored to what they are doing. Does that mean that twin tips are for beginners since almost all of us began on a twin tip?

Not exactly. Twin tips allow riders to do it all, jump big, land easy, turn quick, go far, get it done, and have fun!

No matter what you want to do with the sport, there’s a twin tip with your name on it. However, looking at the array of kiteboarding twin tips can be dizzying, and it can be hard to decode the tech that lies beneath the graphics. How is anyone supposed to find their perfect match?

To answer this question, I started with a Google query that led me to some impressive product pages with beautiful photos, convincing taglines, and a list of tech specs that went over my head. Sandwich construction, rocker, flex, concave, channels, Biax longitudinal reinforcement strips, printed gloss substrate, are you with me? I was a bit lost, so I decided to call on the experts. With help from the best twin tip designers in the business, I’m going to crack open the twin tip market to help you find your Valentine.

First up we wanted to understand the process of how a twin tip is built, what stages it goes through and how a bunch of raw materials end up on under your feet on the water. We asked Lars Moltrup, the Product Development Manager at Cabrinha to give us the skinny on how to make a twinny.

"The process features about ten main steps, but these will be different for each manufacturer. First, a wood core has the outline and inserts machined, at this stage the board still very much looks like a block of wood. Next, the ABS rail and fin materials and the binding inserts are glued into the core. After this, the blank core is machined on a CNC machine, top and bottom and then fixed into a vacuum mould."

"Different boards feature different shapes and more or less machining. During all of these processes, the moisture content is controlled in heat and humidity chambers to ensure the core of the board is as strong as it can be."

"Before the lamination starts, the top and bottom sheet are printed (screen, digital, sublimation or a combination). We then take all the components (top sheets, core and fibres) and stack them in the mould (aluminium or metal) then the resin is applied to the individual components."

"The board is then pressed we use a heating and cooling cycle of about 45-60 minutes; this is the Cabrinha process. It’s worth noting that some manufacturers will only run a heating cycle of a quarter of that time. The longer the board is heated and cooled in sequence the stronger the overall product will be."

"After moulding, the board will be placed in vacuum mould on the CNC again to machine the outline and drill fin holes. Some manufacturers do step 7 entirely by hand, which of course is much less controlled and precise than running the board through the CNC machine again."

"The final touch is to hand finish the product, sand and clean the board. After this, the build process is over, but there are still some stages to go!"

"The quality control team now takes the board and checks all dimensions (inserts, rocker, outline, rail, etc.), the flex is also measured, any imperfections and the board is rejected. If the board passes the tests and is good to go, it gets packaged up and ships to the shop, ready to be sold to you!"

OK, now that we have a better understanding of the process of building a twin tip it’s time to look at how the design comes to fruition. How do concave, rocker, channels, flex, outline, construction and all the other factors impact how the board rides on the water? To answer this question, we spoke to Charles Bertrand, a Naval Architect with a masters in fluid dynamics. Charles is also the F-One R&D Engineer who works on all their boards and hydrofoils. We couldn’t think of a more qualified man for the job on this one!

"The rocker is the curvature of the board when looked at from the side. Less rocker means less curve, which helps a rider achieve early planning and good speed while improving upwind capabilities. More rocker provides more comfort and more manoeuvrability, but it slows down the board."

"The outline is the shape of the board when looked at from the top. The more parallel the rails, the better edging the board will have. A rounder outline will help manoeuvrability. The size of the tips compared to the centre of the board is also important. Larger tips help create more pop and also make for easier landings."

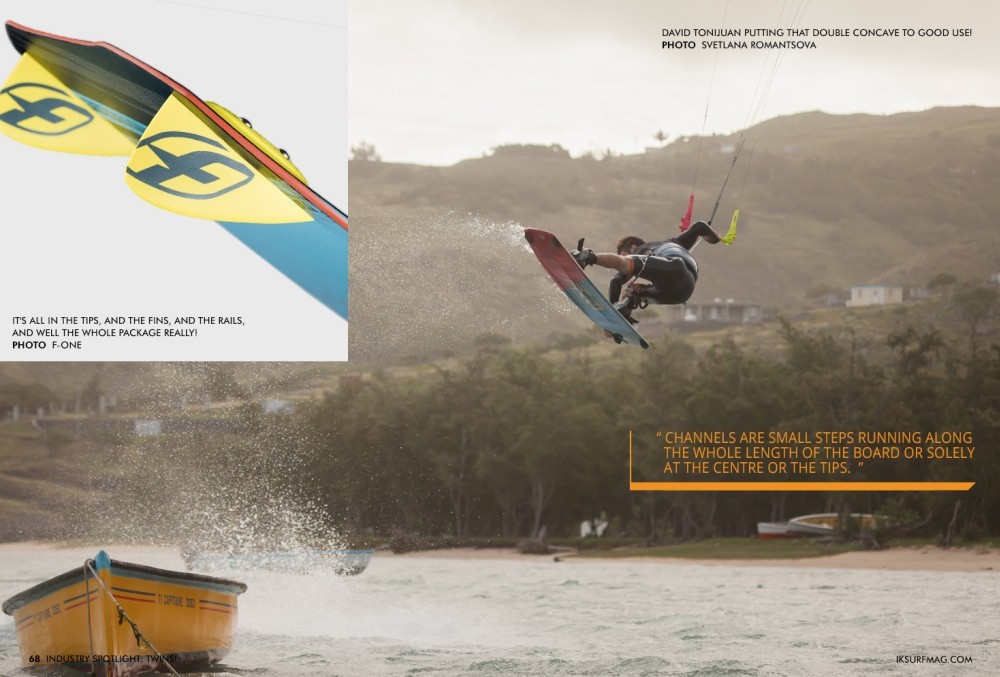

"Concave and channels are features of the bottom of the board. It’s easy to see if you place a ruler along the width of the board. A concave bottom shape makes the rocker curvature different along the central axis than along the rails of the board. The rocker is subsequently stronger along the rails while in the middle of the board it is, in effect, flatter."

"In general, this helps a board achieve earlier planning and better speed without compromising manoeuvrability since the rails have kept the same rocker. Another noticeable effect is that a concave shape absorbs the chop better than a flat one. You can also find boards with double concave, where across the width of the board you will see two concave sections separated by a ridge in the middle. The double concave shape is probably the best for overall comfort and landing stability."

"Channels are small steps running along the whole length of the board or solely at the centre or the tips. Their role is to add grip when edging, and their effect depends on how deep and how numerous they are."

"Both the shape and the construction of the board affect its strength and the way it flexes. Obviously, strength is always something that you want in your board, but since it usually comes with added weight, you have to tread carefully. The flex is simply how the board bends under load. More flex provides more aggressive pop and a more comfortable ride, but too much flex can result in a board that lacks control. This can be tuned by playing with the thickness of the board and the materials."

"The design exercise is a constant compromise, as you cannot push all aspects to their absolute max in one single design. But you can find combinations where specific aspects work together to achieve a better result. In a way, you can compare this to a sound engineer facing an extensive set of sliders on his mixing table. There’s no way he can simply push all sliders to the max. His job is to find the best combination for all of them to reach the best balance that’s going to match the band playing rock, jazz or hip-hop music!"

"My job is to find the best combination of characteristics and blend them according to the purpose of the board and the type of rider who it is aimed for. Each board is different, and this is why it is important to find the best design that suits you and the way you ride. Remember as you get better your needs and therefore your board should change too!"

Now we have a clear insight into the different aspects that go into designing a board and how these attributes will affect the way it will ride. We asked Lars at Cabrinha to explain which features they prioritise when it comes to board design.

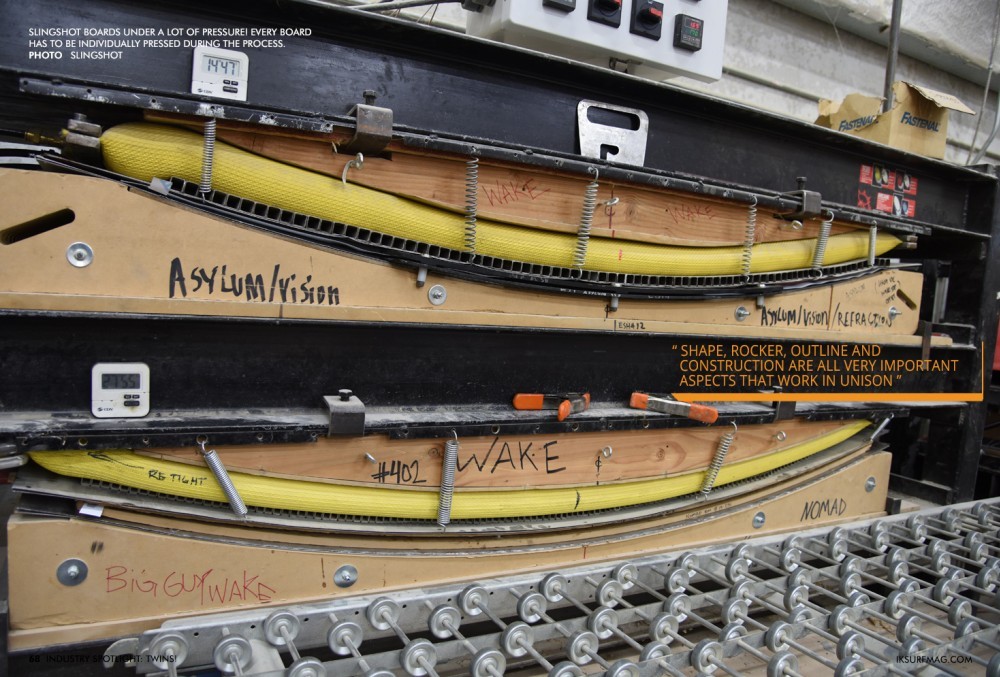

"Designing a twin-tip is all about considering the target user. The most important thing is to prioritise who the board is designed for and in what conditions it will be used. Shape, rocker, outline and construction are all very important aspects that work in unison, complimenting each other. One cannot be considered or altered without impacting other features."

"As an example, if we were to design a Carbon construction, wide tip board with low rocker, this board would work great for going upwind on flat water, and it would have amazing grip and pop. Once you bring the tips in and the rocker up, the board starts to lose grip but improves greatly for riding in chop. However, you might gain some of that grip back by adding channels or modifying the depth or configuration of the concave. So, in short, each feature is dependent and will affect the others."

Technology is always changing, whether it is the materials being used, or the way the board is designed, even the machines used to build the boards are evolving. We spoke to Juraj Bukovcak from CrazyFly about some of the techniques they use when it comes to tech!

"We have a state of the art CNC machine that can create very advanced shapes on the core of the boards. It can shape the wood core with one-thousandth of a millimetre precision. The cores of our boards in some areas, mainly toward the tips, are only one millimetre thick. Even at this very thin depth, the CNC can still shape concaves or angled shapes. The rider feels and benefits from these advanced shapes."

"If you compare our current shapes (double, triple, quadruple concaves etc.) with shapes from five years ago, it is almost incomparable. The older shapes had single concaves on the bottom and no 3D shapes on the deck. The newer boards simply ride much better-- there is no question about this."

"Also, our custom built moulding machines and moulds for the boards have advanced a lot thanks to new technologies and can mould the advanced shapes mentioned above without any problems. We increased the pressing strength and mould pressure to ensure even distribution of the resin so that the advanced 3D shapes are formed correctly."

"The CNC machine and the moulding department are the heart of our twin tip board production, giving each twin tip its soul."

From an outsider’s point of view, it would be easy to view all twin tips, as being the same, after all since the revolution of 2005 when North launched the first Jaime Pro using snowboard construction, not much appears to have changed at face value. However, as we have learned these boards are continually evolving and being developed even further. Take a board from five years ago and compare it to a board from this season and there will be some stark contrasts. We asked Philipp Becker from North Kiteboarding what the twin tip of the future would look like…

"We’ve seen quite a range of lengths, widths, rockers, channels, outlines and constructions over the years, and we’ve experimented a lot to find the shapes and flex patterns that can be seen today. They all fit perfectly into the model and purpose it’s built for. The snowboard technology, which we implemented into the market via the first Jaime board years ago, is still a benchmark today. Future developments will aim for even less weight without compromising on durability."

“Shapes will continue to evolve, however, the main thrust of development will be in reducing the weight and maintaining strength. Materials like Textreme Carbon allow us to get closer to these goals and we are always searching for better, more improved materials. Finally, we are always striving to make a greener kiteboard, our factory in Austria moves us even closer to that goal. Be sure to check out the video in this article; it’s an incredible place!”

Many riders crossover to surfboards or foil boards soon after they can stay upwind. Should kiters consider sticking with, or going back to, twin tip riding even after they’ve passed those early stages of their progression? We asked Nesan Furtado, the marketing coordinator at Ocean Rodeo, and Mark Shinn, founder and Shinn how they felt about riders choosing to ride something different!

Nesan Furtado: "As with most sports, the fashion of what’s in is always moving around. With modern kite technology combined with the latest twin tip boards, the result is a rejuvenation of kiteboarding’s roots, big air! With events like Red Bull King of the Air, it’s great to see kiteboarding getting back to what made us want to learn in the first place-- jumping huge!"

"We feel the big air discipline of kiteboarding is the true heart of kiteboarding, unique to our sport and not borrowed from surfing or wakeboarding. This is why it is important that riders don’t forget the rush of boosting a huge air on a twin tip. Everyone should definitely have one in their quiver for those windy days!"

Mark Shinn: "Riders should do whatever they want to because this is a free sport and the only thing that is important for any of us is to enjoy our riding. Having said that, I would say that the most often forgotten aspect of kiteboarding is kite control and the best way to do that is to spend a lot of time on your TT!"

As we know, our sport isn’t the greenest. Most water sports embrace the eco vibe, yet we struggle to implement it when it comes to creating the toys that make us smile. North Kiteboarding have been leading the way in looking to a greener future, so we asked Philipp Becker how they were getting on reducing the environmental impact.

"Of course, we’re trying to produce in a sustainable and environmentally friendly way. Our production facility in Austria is a leading example when looking at the materials used throughout the process, as well as being powered by hydro energy. The location in central Europe helps to keep transport distances to our main markets down. Packaging is a constant challenge, and we’re working on reducing plastic more and more."

"We’re always striving to improve in this aspect and with time and further developments within the industry a cleaner, greener future is definitely on the cards."

Now that we understand how a board is built and how various design elements influence performance, all that’s left to do is find a board with agreeable graphics and get on the water! Let’s say I choose my board purely for the graphics, can I really go wrong? I asked Gary Siskar, Global Brand Manager at Liquid Force and Maciek Jazwiecki Chief of Marketing and Communications at Nobile that very question!

Gary Siskar: "I do that… but then I also get to choose what graphic goes on what board! Seriously, if you are going by the graphic alone, you might be satisfying your emotional, cool side but hurting your physical performance side. You should always choose the board that best suits your riding style if you can, but equally if you hate the way it looks you won’t enjoy riding it so much haha!"

Maciej Jazwiecki: "I think it’s obvious that you ride better on a prettier board, right? Haha! However, don’t forget to match the equipment with your style, weight, height and water conditions you kite most often. At Nobile, we work really hard on the graphics and run a competition each year with design companies where we ask them to come up with a theme for the collection. This has resulted in some stunning graphics and themes that run across all the boards. Our latest Tribe and Futurism collection for 2018 was designed by the Polish arm of the Saatchi and Saatchi design agency!"

I think that last point really sums things up; you can choose a board based on the colour and the price, and it won’t be the end of the world. However, when you consider how much work and thought goes into making these boards, then you’d do well to make an informed purchase instead. We’d recommend critically analysing your ability, the style of your riding and where you ride. Then take that information and look at several brands and see if they offer a board that will suit you. Once you’ve got a shortlist, then you can start to let things like the colour, price and even brand loyalty come into play.

Of course, the other alternative is to go with the advice of your local shop; you might even get to demo a board and find out which one suits you best on the water. A good twin tip can last you for years, so it’s well worth investing in one that is right for you. Oh, and if you’ve not ridden a twinny in years because you’ve “moved on” maybe sling one under your feet again see what you’ve been missing. Boosting to the moon and back has never felt so good!

Videos

By Lindsay McClure

Lindsay is a pro rider from Hood River in the USA, she works for IKSURFMAG as our Features Editor and is an integral part of the team. Lindsay is really into wakestyle riding and can be found in the Hood River Slider Park during the summer months, she also travels all over the world with the World Class Academy helping younger riders develop through kiteboarding!