Behind The Brand - Nobile

Issue 57 / Sun 12th Jun, 2016

Rou Chater flies over to Poland on a strike mission to visit the Nobile factory and discover just what an influence Dariusz Rosiak has had on our sport.

If you kitesurf today; you owe a lot of the technology under your feet to Nobile and Dariusz Rosiak. You might not know it, but the Polish brand has been at the forefront of kitesurfing development since 2003. Their roots, however, go back much further than that.

In 1994 Dariusz Rosiak was a passionate Polish snowboarding pioneer who’d just sold his wine bottling business and figured there was a niche in the market for building snowboards. He picked up some old machinery from a ski factory, set up Nobile, made his first snowboard and went to ISPO, the huge sporting goods trade show, to drum up some customers. His hunch was right, and after walking around the stalls for a few hours, he already had more orders than he would be able to fulfil.

It wasn’t long before Burton Snowboards came knocking at the door, and Nobile was soon making a considerable number of the boards found on the slopes. Fast forward a few years and Dariusz discovered a new passion in kitesurfing. He had been a keen windsurfer for many years and spotting this new sport in 2001 had instantly wanted to give it a try. Something I think we can all relate to!

His talents in previous board sports helped him pick up kitesurfing quickly, and it wasn’t long before his engineering brain was dreaming up ideas and concepts.

At the dawn of our sport, a period many of you are blessed not to remember, kiteboards were made in much the same way as windsurfing boards. They used foam blanks, shaped and glassed to produce a thick, stiff board with surfboard like rails. They were notorious for snapping, especially as the riders increasingly pushed the limits of the sport with bigger and bigger jumps; they also often had the flex characteristics of a log.

Dariusz had a snowboard factory, and he felt a snowboard style construction, with good flex, would be better suited to kitesurfing, the boards would also be infinitely more durable too. Till Eberle was in Germany at the time heading up the North Kiteboarding brand, he knew Dariusz from his snowboarding days, but more importantly Fanatic, under the same parent company as North, were producing snowboards in the Nobile factory. When the two of them got together, it seemed only logical to explore this radical step forward in kiteboard construction.

Dariusz built the first prototype in 2003, and the biggest test was to see if a wood core board with a glass laminate would even float. Dariusz and his team used a fire protection water tank at their factory to lower this first kiteboard into the depths to undertake an all important float test. It was a success, and Till and Dariusz set to work on changing the face of kiteboarding forever.

Till and the North designers provided the shapes and graphics, Dariusz and the team at Nobile provided the technology and construction processes. The North Jaime Pro from 2004 went on to become the best-selling board of its time and in subsequent years outsold almost every kiteboard on the market.

The floodgates opened, and today every kiteboard in the industry uses the same basis of construction pioneered by Nobile back in 2004.

In 2005 the brand moved into new factory premises across town from their original base. The leviathan of a building they operate from now is a testament to the sheer volume of snowboards Burton were selling. Burton accounted for 80% of their custom at one time, although Burton no longer produces their boards here.

Nobile still boasts 38 customers from around the world making kiteboards, wakeboards, skis and snowboards for many well-known brands. More famously though, they have their very own range which is one of the biggest in the industry under their Nobile moniker.

It’s this depth of experience and diversity that helps the brand continue to push the development of kiteboards today. By utilising and trialling various technologies across a wealth of sports and customers they end up with the latest construction techniques and the know-how to push the sport ever forwards.

Two numbers probably sum up the Nobile brand to lots of people, 555 and 666, the flagship boards that put Nobile firmly on the map in 2005. The 555 defined what freeride kitesurfing was all about before it existed as a genre, while the 666 packed a hefty amount of performance and technology into a fantastic shape that offered extreme pop and freestyle capabilities.

These boards quickly became best sellers and, believe it or not, can still be seen going strong on beaches today. Nobile always build their boards to last, something that can be counterproductive when you want someone to buy the latest model, yet they would far rather garner the trust of the customer and create a superior board than have to deal with warranties and a short lifespan with their products.

When Nobile launched their first kite range in 2007, it was a testament to their fastidious production and development processes. The 555 and NHP kites arrived on the market with just about every bit of modern technology you could wish for, plus the rather ingenious Fulcrum Release System.

Safety is always a big concern for kitesurfers and after a nasty accident on a beach in Brazil, where Dariusz got dragged for 3km by a death looping kite. He was left bruised and battered (and minus most of his skin) to ponder on the notion of producing a safety release that worked reliably. After two years of development the ideas had come to fruition and it was time to launch this new release system alongside the kites.

The Fulcrum Release was the first fully moulded chicken loop and release mechanism on the market. It was radically different from anything we had seen before in the industry, and it was beautifully simple too. It was another example of Nobile not being afraid to buck the norm and venture down a unique path - something they still do to this very day.

Behind all of this development is the relentless mind of Dariusz Rosiak, constantly trying to improve his time on the water and at the beach to make kitesurfing a better sport for everyone. The list of innovations he has conjured up seems endless, and there probably isn’t a kiter, skier or snowboarder on the planet who hasn’t benefitted from his visionary improvements at some point during their pursuit of fun. Whether that is directly through the Nobile brand, or indirectly through one of the many brands they produce for, is immaterial. The influence Dariusz has had on the sport can’t be understated.

To list all the technological developments in this article would prove futile, but click HERE to head to their tech page on the website and feast your eyes over some of the innovations Nobile have developed into their boards. Perhaps the most important, and the one that sets them apart from the rest is the Added Pre Stress technology or APS as they call it for short.

First launched in 2010 this technique loads the core of the board with energy during production. Making the board stiffer and gives more torsional control while offering extreme pop when you release the energy after loading the board for a jump.

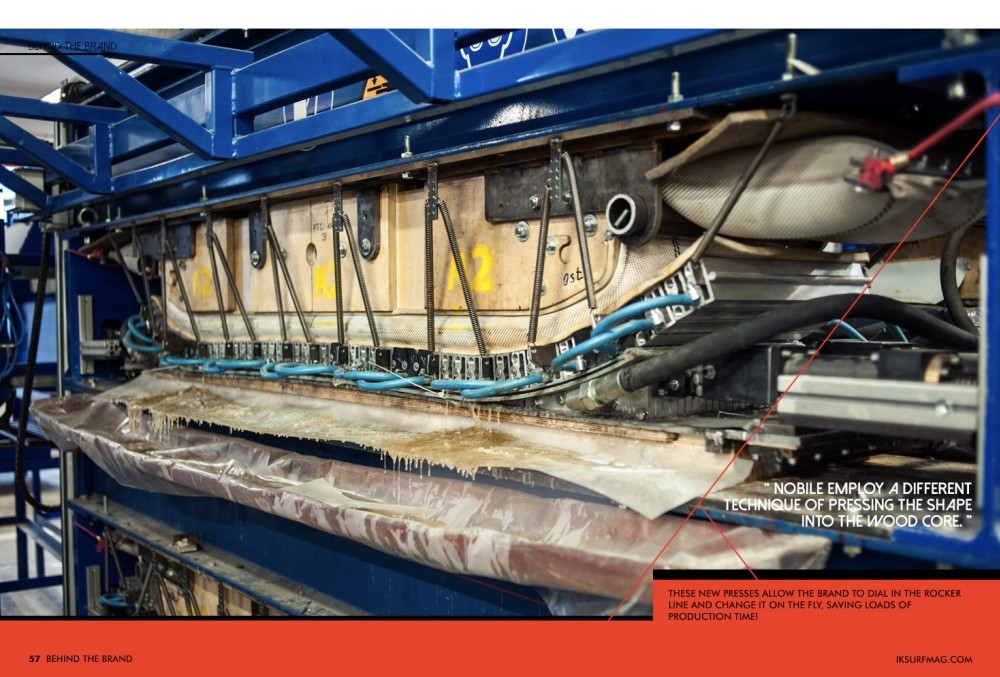

A lot of boards these days feature a CNC’d wood core with channels in the base for added grip and stability. These channels also help to soften the landings and break up the surface tension of the water. Rather than CNC the base of their wood cores Nobile employ a different technique of pressing the shape into the wood core. Increasing the Pre Stress again and also makes for a much lighter, thinner and more responsive kiteboard.

Perhaps the biggest development in twin tip technology recently has been the split board, again pioneered by Nobile. The FlySplit from Flyboards is made here in Poland, as well as the Nobile range of Split Boards of course. Both brands use slightly different pin systems to secure the join, but the W connection is regarded as the strongest, stiffest and most reliable.

During the production process, Nobile adds extra glass to the connection area to ensure it can never break. After testing these boards to the limits, they went on sale for the first time in 2013. For kiters who travel and don’t want to pay extra fees at the airport, they represent a huge step forward in board design. At the moment the NHP Split is their best selling board, outselling all of their other boards combined!

The boards are a little softer than a standard board, by about 20%, but that just makes them even smoother through the chop and more comfortable to ride. With a growing army of fans around the globe, it looks as though Dariusz hit the zeitgeist once again in terms of what kiters want.

As I wandered around the factory during my tour, I was blown away by the scale of the place. With huge rooms filled with CNC machines, high tech equipment spanning three floors and a full staffing complement of around 200 people during the peak production season, it’s fair to say Nobile are a major player. Having a capacity to produce 100,000 boards and skis a year using the very latest techniques, it is easy to see why so many customers want to get their boards built by Nobile.

There is a family feel to the building as you walk around too, Gosia Rosiak-Brawanska, Dariusz’s daughter and the CEO of Nobile explains that they all share a common passion and strive to produce the best quality boards and skis. They organise social events for the staff and also in the winter if there has been a fresh powder day they will often meet on the mountain rather than at the factory to start the day's work. Some of the workers have become couples and even gone on to get married; I got the impression that this would be a good place to call work.

The innovation doesn’t stop at the factory floor either; they think out of the box in other ways too. Maciej Jazwiecki, Chief of Marketing at Nobile, had the idea to send a brief out to all the big design agencies and see if they would bid for the chance to design the collection for the brand. Gosia wasn’t convinced they would want to, but when Saatchi and Saatchi, Greys, DDB and everyone they invited came back to them with designs saying they would love to work with the brand she realised the genius in Maciej’s plan.

The first year this happened resulted in the Saudade collection developed by the Grey advertising agency for the 2015 collection. For 2016 the DDB advertising agency created Earth and Space as a theme for the collection and next year in 2017 we will see another completely different collection from Kopen Hangen, a design team in Krakow. It’s an interesting approach that keeps the board range fresh and dynamic and adds a bit of a story to the graphics too.

The Nobile Kiteboarding arm of the business is based in-house at the factory in Bielsko-Biala. 15 people work full time on the shapes, designs and marketing. In addition to this, Nobile have their pro riders and ambassadors dotted all around the globe.

Gosia explained: “We aren’t looking for the best riders in terms of performance, yes that is important, but we want personality too. Our team has to be approachable and happy to spread our message to the public.”

“We work a lot with kite schools too; they can offer us a different insight in terms of testing our gear, and also different feedback from the pro riders who might only ride a couple of boards in the range.”

Eudazio Da Silva is their big card in terms of freestyle; the Brazilian is up there with the best of them, but like so many pros, he has sadly succumbed to injury and is currently being looked after by the Nobile team in Poland where he has had surgery and is undergoing rehab - another nod to the family nature of this business that I mentioned earlier. He’s hoping to be back on the water in 6 weeks and has his eyes firmly set on the world tour in 2017.

Katarzyna Lange is another key player within the pro team. She runs a popular kite school in Poland and also participates in some of the slider and kicker events around the world. Again, Gosia sings the praises of Katarzyna and her ability to communicate with the public about the benefits of the brand, which is key to Nobile’s ethos.

I asked Gosia about the future direction of Nobile, and if they had anything in production to be launched soon. It seems that Dariusz has caught the foiling bug as their next big product launch will be a hydrofoil, but one with a twist… The new Nobile Hydrofoil will fit into a bag that can be checked in as regular luggage!

By utilising their split board technology, and three different sized masts, they have created a package that fits in a stylish bag you can happily load onto an aeroplane without paying any fees. There is a 60cm mast for learning, an 80cm for freeride and easy travel and a 96cm mast for performance and racing. The foil uses aluminium and glass to keep the costs down and the prototypes I was lucky enough to see looked very impressive!

There is a passion that is alive and well at Nobile, something that is clear to see as you walk around the factory. It starts at the top with Dariusz and filters down through the rest of the team. They are always striving to make kitesurfing better, whether through advanced construction techniques, or innovations for the sport. I’ve always been a fan of the brand and the equipment they create, but after such a deep insight into how much effort and passion they put into everything they do I left Poland highly impressed.

It’s people like this that our sport needs, innovators, dreamers and doers. Nobile is a family which strives to make a difference to our daily lives at the beach and ensure that kitesurfing just keeps on getting better and better!

Videos

By Rou Chater

Rou has been kiting since the sports inception and has been working as an editor and tester for magazines since 2004. He started IKSURFMAG with his brother in 2006 and has tested hundreds of different kites and travelled all over the world to kitesurf. He's a walking encyclopedia of all things kite and is just as passionate about the sport today as he was when he first started!