Brainchild Ralf Grosel

Issue 112 / Tue 19th Aug, 2025

In this IKSURFMAG feature, we explore how Brainchild Manufacturing grew from a 1,000 m² workshop in North Macedonia to one of kite and wing production’s most innovative forces in just two years. From stitch-free ProWeld technology to digital printing, they now produce kites for Reedin, F-ONE, Harlem, and Juniqua and with a new 3,000 m² facility coming soon, Ralf Grösel is set to push innovation even further. Find out more here!

When Ralf Grösel first opened the doors to Brainchild Manufacturing in North Macedonia, it wasn’t just another kite and wing production facility. It was an ambitious experiment; a “laboratory-first” approach to pushing the technological limits of kitesurfing gear, while embedding sustainability into the very bones of the business.

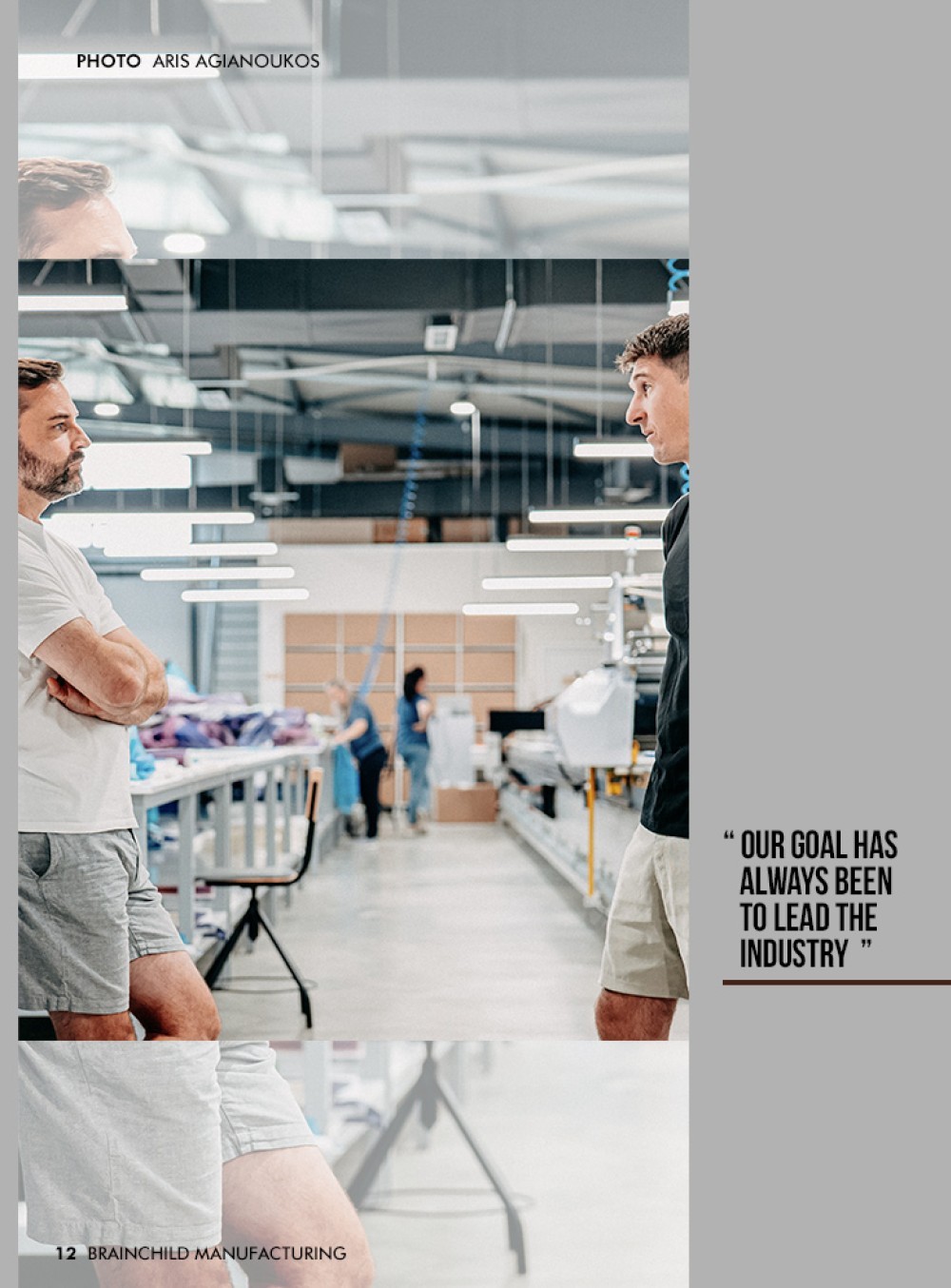

Two years ago, Grösel was working out of a modest 1,000 m² space with just a handful of employees and one or two early prototypes. Today, Brainchild has grown to over 150 staff; soon to be 200; and is on the cusp of moving into a new 3,000 m² manufacturing facility. The split between the laboratory and a full-scale production site will, as Grösel puts it, “finally make my original vision possible; a place where we can innovate without the constraints of mass production”.

Once the mass production facility is complete at the start of 2026, Ralf will be free to use the Lab to focus on new materials, techniques and technologies for producing kites and wings. Ralf is looking forward to focusing his time solely on development, and he has a production manager, Svetlana, already in place to take over the production arm of Brainchild and ensure that standards are kept to Ralf’s exacting levels.

From Idea to Industry Influence

When Brainchild launched, Grösel’s aim was simple but bold: to set new standards for the industry. That’s exactly what he believes has happened.

“In the beginning, we were just prototyping,” he recalls. “Now we’re producing for four major brands: Reedin, F-ONE, Harlem, and Juniqua. Our goal has always been to lead the industry in both innovation and execution, and I think we’ve proven that.”

The results are visible on beaches worldwide, particularly in the high-profile big air scene. Although Brainchild never set out to focus solely on that niche, the unique flight characteristics of their kites, light, agile, and incredibly responsive, have made them a natural fit for riders pushing the limits. In a discipline where margins are so small, from the height of the jumps to the chances of failure during an extreme move, riders need the ultimate equipment to power them to the top of the podium.

The Casati brothers often fight for the top step of that podium, a testament to how Brainchild has proven itself by providing high-quality production and cutting-edge technologies to brands like Harlem. Who, in turn, combine these to make event-winning products for some of the best riders in the world. Brainchild isn’t solely focused on big air, but it seemed a natural place to test their products and showcase them before focusing on other areas of the sport.

ProWeld: Stitch-Free Strength

One of the standout innovations is Brainchild’s proprietary ProWeld seam technology. Traditional kites rely on stitched seams for their leading edge and struts. ProWeld bonds the segments of the leading edge without stitching, producing a stiffer frame that improves performance while significantly reducing weight.

“For a designer, it’s a massive step,” Grösel says. “I can create a better frame that is lighter and more cost-effective than something like Aluula, and still have it outperform in stiffness. In fact, our kites are often lighter than the Aluula competition.”

That journey hasn’t been without hiccups. Transitioning from making a handful of kites and ramping up to thousands caused a few issues early on. To combat this, Ralf brought in a team from the car industry to raise quality control to new levels. “Murphy’s Law applies,” he muses. “Everything that could go wrong, did. But we fixed it, usually within a day. Now the process is solid.” We brought in experts from the automotive industry, who are used to working to exceedingly high standards. This influx of talent helped us take what was achievable at a prototype level and replicate it repeatedly during mass production while simultaneously minimising failures.”

These days, the production at Brainchild Laboratory is really polished, and Ralf is looking forward to moving to the new manufacturing facility. The processes and techniques they have developed in the Laboratory will ensure a seamless step to full-sized manufacturing. Every Brainchild product we have seen has impressed us with the build quality and finish. The team here is really working hard to ensure that every kite that gets to the customers is perfect.

Digital Printing: Design Freedom and Weight Savings

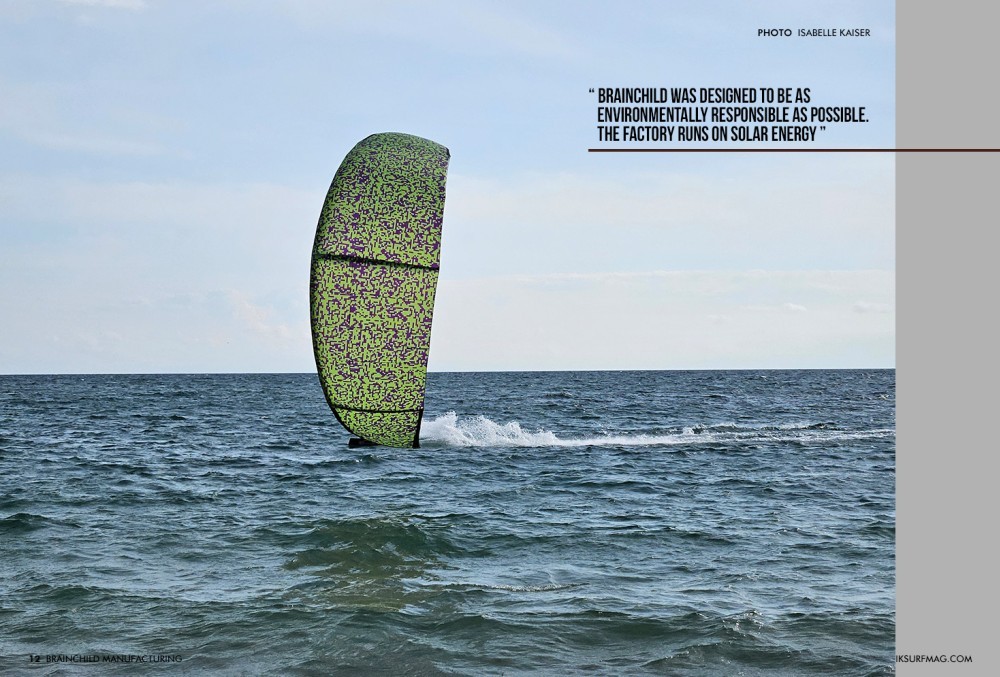

Another signature Brainchild innovation is full digital printing directly onto white canopy cloth. Rather than cutting and stitching panels of pre-coloured fabric, which adds weight and waste, Brainchild prints designs directly onto the material.

“It’s lighter, it saves material, and it lets us create more dynamic graphics without compromising the canopy,” says Grösel. “And because we only buy white material, some of it in its natural, unbleached state, we also reduce the environmental impact at the source.”

This digital-first approach is also faster in production, helping keep costs down without cutting corners. It also gives Brainchild its unique look on the beaches. Whether it’s a model from Reedin, F-ONE, Juniqua, or Harlem, you can instantly spot it’s a Brainchild from a distance. Digital printing allows for much more freedom in terms of visual design. “We’re now starting to see other brands copy this technique, which is fine, but it proves our concept even more”, Ralf says, “Digital printing is better for the environment, better for production and kite design, and gives a lighter and visually more exciting product to kitesurfers.”

Chasing Lightness Without the Price Tag

While competitors have leaned heavily on high-cost exotic laminates, Brainchild has taken a different path, achieving comparable weight and performance without inflating retail prices.

“We use the lightest canopy material available, which we developed with our suppliers, plus optimised panel layouts, leading-edge diameters, and bladder materials,” Grösel explains. “It’s the sum of all these variables. Every little decision saves weight.”

A lighter kite is a better kite. In our sport, where the kite has to fly, it’s important to make it light as it will fly in less wind and be more responsive in the air. This gives the rider a better feeling at the bar and a much more enjoyable and dynamic session on the water. Of course, we still need to make this sport accessible, and this is something Ralf is very passionate about. “There is no point in having the lightest gear if no one can afford it. Aluula is a great material, but its high cost at the source means the price tag is really high when it is built into a kite. Here at Brainchild, we reduce the weight of everything we do; the sum of all of this gives you a lighter kite without an exceedingly expensive base material like Aluula.”

That focus has led to kites like the Harlem Force and Reedin Whisper; lightwind machines that combine ultra-low weight with agile turning and rock-solid stability. The weight savings are noticeable across all of the kites. However, every kite from the Brainchild factory is similar in weight to an Aluula equivalent, with a more affordable price tag.

Design Partnerships Across Four Brands

Brainchild’s model isn’t just about manufacturing; it’s about collaborative design. Ralf personally designs or co-designs kites for each of their four partner brands, adapting to each brand’s unique DNA. After spending over 20 years designing some of the most iconic kites in our industry for Duotone, there isn’t much he doesn’t know about kite design, but each brand has its own unique “style” when it comes to how its kites fly.

“An F-ONE kite flies differently from a Reedin kite, and Harlem has its own feel again,” he says. “The challenge is to improve the product without losing the identity that customers love.”

Recent projects have included the upcoming F-ONE Bandit, where Grösel stepped into the lead designer role for the first time. “I didn’t want to screw up such a legacy product,” he admits. “It took a lot of prototypes, but working closely with Raphael and his team, we found exactly the balance we were aiming for.”

It’s a challenge to work with all of these different brands and to be able to design kites that their loyal fans are going to love, but if there is one thing Ralf loves, it’s a challenge. He’s also learning a lot along the way, and getting input from other designers just makes the finished product even better for the customer. It’s a holistic approach to kite design that he firmly believes benefits not only the brands he works with but also the customers who buy the products.

Sustainability Built-In

From day one, Brainchild was designed to be as environmentally responsible as possible. The factory runs on solar energy, with any surplus fed into the grid. Materials are sourced locally from Europe where possible, reducing transport emissions. Even the packaging is made from recycled material produced nearby.

“It’s about making the smartest possible decisions,” Grösel says. “If you have the chance to reduce waste or energy use, you should. It’s not utopia, but it’s about doing the best you can.” Taking things further, the team also looked at particular machines that used high energy and have started to replace them with more efficient options, all while retaining the high-quality standards Brainchild is known for.

The new manufacturing facility will continue this approach, with an even larger solar array aiming to produce more energy than the factory consumes. It’s not a destination, especially in our sport, where being eco-conscious is tricky, but the journey Brainchild is on in terms of sustainability is one of the most impressive in the industry and hopefully a beacon for the industry to follow.

A Healthy Dose of Competition

When Brainchild first launched, it caused quite a stir in an industry that has always been fairly closed behind the scenes. To have a new factory offering new technologies at a very eco-conscious level was a dilemma. Would brands carry on production as they always had, or would they adopt some of Ralf’s ideas?

For Grösel, competition is a motivator, not a threat. “We set the standard, others copy; and that’s fine,” he says. “It proves the idea is good, and it pushes me to set the next standard. That’s how the sport grows.”

We’re seeing more and more eco-focused offerings in the industry now, from wetsuits to boards and everything in between. The goal has shifted, which can only be positive if the customers demand a better way for the environment, which the brands and factories must follow. Ralf is happy to lead that charge and see his ideas spread. It’s a refreshing attitude that is needed in this world.

Kitesurfing’s Future

Despite industry challenges in recent years, from COVID highs to post-boom overstock, Grösel is bullish on the sport’s future.

“Kitesurfing isn’t going anywhere. It’s safer, more accessible, and more fun than ever. As long as people leave the beach with a smile on their face, there’s life in the market.” It’s important to remember this, as a key part of an industry that is struggling, it’s easy to get bogged down. Still, we have to remember, as Ralf points out, that kitesurfing is fun, people will always do it, for sure, and other sports will come along, but kitesurfing will always be around, and as long as we can keep it fun, safe and accessible for everyone, it will be here to stay.

From a handful of prototypes to an industry-shaping operation, Brainchild Manufacturing has proven that innovation, sustainability, and smart design can coexist. As the company prepares to move into its next phase, Grösel’s mission remains unchanged: to keep pushing limits in the lab, on the water, and for the sport itself.

“I’ve been chasing performance my whole life,” he says with a grin. “The moment you achieve something, the challenge is to make it even better. That’s what keeps me going.”

By Rou Chater

Rou has been kiting since the sports inception and has been working as an editor and tester for magazines since 2004. He started IKSURFMAG with his brother in 2006 and has tested hundreds of different kites and travelled all over the world to kitesurf. He's a walking encyclopedia of all things kite and is just as passionate about the sport today as he was when he first started!