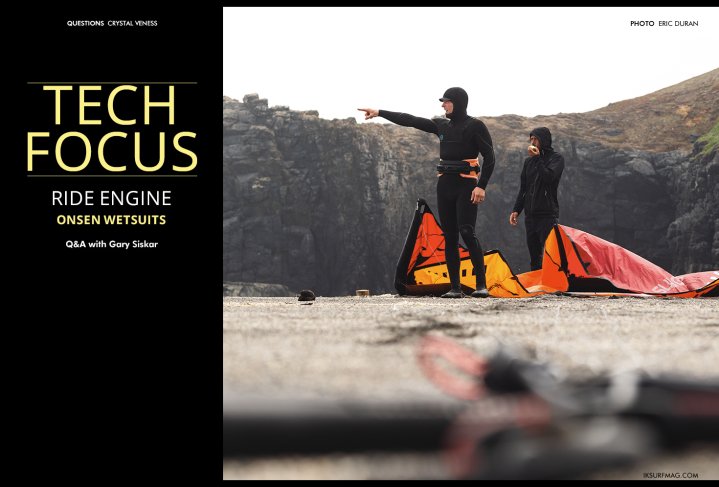

Tech Focus: Ride Engine Onsen Wetsuits

Issue 102 / Thu 14th Dec, 2023

The Onsen is the newest wetsuit model in the Ride Engine lineup, featuring #40 Yamamoto neoprene and available in both men's and women's suits. Brand Manager Gary Siskar tells us all about this special material and all of the other elements that make the Onsen a top-quality wetsuit!

Gary, tell us a bit about what makes the Yamamoto neoprene so special!

This neoprene is unequivocally the finest choice for a performance wetsuit in the realm of water sports we're all passionate about. To draw some comparisons, Yamamoto #40 can be likened to utilizing the highest-grade Gore-Tex in outerwear, or, within our own industry, it's akin to the benefits of using Aluula in kites and wings.

How is Yamamoto neoprene produced? What makes it such a sustainable and environmentally friendly option?

Yamamoto neoprene stands out as one of the most environmentally conscious limestone-based neoprene raw materials. Its sustainability journey begins at the mining stage and extends through the entire production process, culminating in the creation of end products. The factory employs 100% renewable energy, ensures a safe working environment, and incorporates eco-friendly practices, such as using recycled material for liners, avoiding the use of solvents or additives, and relying on non-petroleum-based rubber—all of which contribute to its eco-conscious approach.

What goes into choosing a new material like Yamamoto? Does the team experiment with several different materials before choosing the best one? What made the #40 Yamamoto the best choice?

Material science is a cornerstone of our focus at Ride Engine, and indeed, we conducted extensive testing on various iterations of wetsuits made from eco-friendly neoprene. What struck us were three distinct advantages associated with the use of Yamamoto #40 neoprene.

First and foremost, it offers exceptional warmth. The honeycomb cell structure, unique to Yamamoto #40, efficiently traps body heat, resulting in a wetsuit that keeps you comfortably warm. We discovered that it allowed us to comfortably transition from 3/2 to 4/3 temperatures and from 4/3 into 5/4 territory.

The second standout quality is its remarkable elasticity. The material's superior stretch capabilities exceeded those of many other neoprenes, making the suit less tiring to wear and significantly simplifying the process of putting it on and taking it off.

Lastly, durability is a key strength of Yamamoto #40. It possesses a notably high "memory value," enabling the wetsuit to maintain its high-performance fit over an extended lifespan.

Ride Engine wetsuits are well known for being flexible and quick drying. Outside of the Yamamoto material, what other design changes have been made in the Onsen range?

We did some significant work on the entry and closure of the suit. We wanted to reduce the "flushing" even more, and we ended up with a great pattern that accomplishes just that without sacrificing the ease of getting in and out of the suit. In addition, we added sizes to both the men's and women's, including tall and short in the range to achieve the perfect fit.

The blue inner lining really pops! What is the material, and what performance elements does it offer the Onsen wetsuits?

That is our Thermal Lock fleece liner. This liner has a few nice benefits. First, it adds a layer in key areas based on the thickness of the suit to increase its thermal abilities. The second is the nice feel on the skin. And lastly, it dries extremely fast!

The Onsen uses glued, blind-stitched, and tape-sealed seams. What led the R&D team to choose these methods of sealing seams? How much do these extra levels of protection improve the water-tight elements of the wetsuit?

Glued and blind-stitched seams are the industry standard for high-performance wetsuits, universally effective in preventing water infiltration. To provide an additional layer of protection, we fully tape the interior backing of these seams, ensuring a water-tight seal.

What sets our approach apart is our decision to move away from using a Power Seam in our previous wetsuit model. While a rubber-coated external seam effectively blocks water intrusion, it is less resilient against the elements, requiring careful maintenance over time. Our commitment is to deliver wetsuits with extended service lifespans, and we firmly believe that using glued and blind-stitched seams with taping is the superior method to achieve this goal.

There are several features designed to keep water out of this wetsuit, including the glide neck skin, matrix-dot wrist grips, and ankle drain holes. How much testing goes into these products to identify the issues and areas for improvement?

Testing constitutes an essential phase for all Ride Engine products. We are fortunate to count among our ranks some of the most accomplished athletes who actively participate in our testing protocols. Our team of alpha testers includes former professional tour surfers and world champion kitesurfers, along with a diverse community of beta testers, all of whom collaborate in the rigorous evaluation of the features integrated into our products.

Videos

By Crystal Veness

Editor at IKSURFMAG, Crystal Veness hails from Canada but is based in South Africa. When she isn't busy kitesurfing or reporting on the latest industry news for the mag, she is kicking back somewhere at a windy kite beach or working on creative media projects.