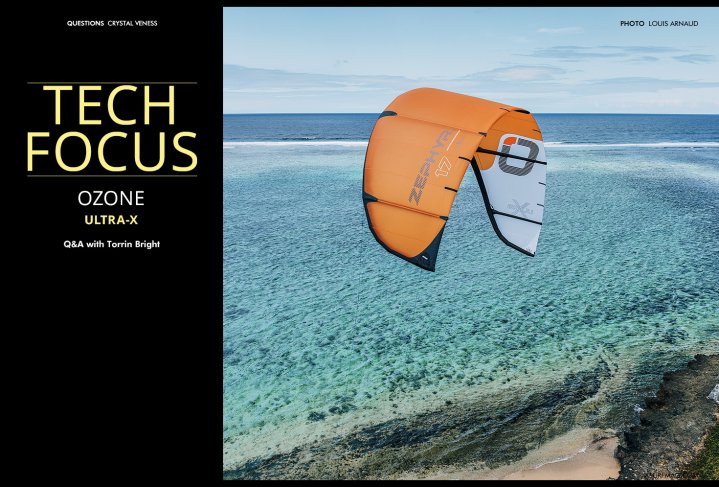

Tech Focus: Ozone Ultra-X

Issue 102 / Thu 14th Dec, 2023

With the latest Ozone Reo and Zephyr being released in the Ultra-X editions, all eyes are on the new Ultra-X range! Ozone Product Manager Torrin Bright talks all about their approach to lightweight design, high-performance products, and a sustainable approach to the kite industry in this technical Q&A!

Ultra-X is not a material but rather a lighter-weight approach to kite development. Can you go into a bit more detail about the Ultra-X philosophy?

Ultra-X is our umbrella term/category for any product that is made using specialist materials that are designed to perform above and beyond the 'industry standard'.

Ultra, with the X factor: performance increases from being ultra light, ultra responsive, ultra stiff… ultra whatever we think will deliver the highest performance.

What drove the development of this new range from Ozone? What were the goals of the design team?

Our aim with all products is always to ensure there's excellent aerodynamics at the heart of every design, but with the Ultra-X line, we wanted the space to offer an even higher performance option, and this has driven development in all areas.

The overall goal was to find reliable materials that are lighter, faster, and more responsive while maintaining strength and durability.

Ultra-X was first applied to the latest Reo V7 wave kite and now also features on the updated Zephyr V8! Tell us about why it was first applied to these products.

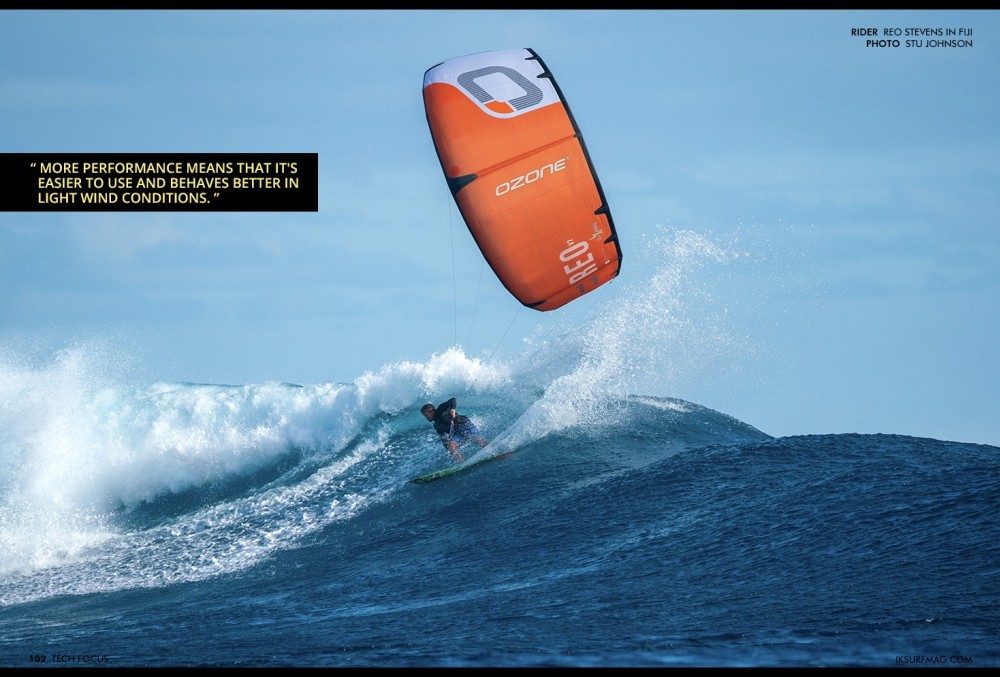

We have two models of the Reo V7, that's true, but decided that for our pure lightwind kite, the 17m Zephyr, that the performance benefits that lighter Ultra-X materials bring also make general riding easier in light wind conditions. In this case, more performance means that it's easier to use and behaves better in light wind conditions.

The Ultra-X option for the Reo is for those willing to pay more because high speed and the most agile handling wave performance mean everything.

The materials we choose really depend on what the rider who will use that product really needs. No more, no less and no unnecessary shiny bits that only add weight.

Looking at the weight of standard Ozone kites, they are already super competitive compared to other leading brands. How much lighter is an Ultra-X model compared to a standard Ozone model? How much lighter can you go?!

We have always believed in designing lightness and strength into products to be as efficient in flight as possible. Naturally, the lighter the kite or wing is, the better it will fly. The stronger it is, the longer its performance will last.

Ultra-X models are in the range of 20% lighter, or sometimes more, compared to the same design built with standard materials. Despite being around 20% lighter, all Ultra-X materials are proven to deliver integral strength, too. The team of expert sewers and material technicians in our in-house production facility ensure that all our designs are born light but genetically strong.

Take us through the process of discovering or developing the materials used in the Ultra-X range. What was the Ozone development team looking for, and what materials did they decide on for the canopy and leading edge/struts?

We don't call materials by any other name for the benefit of marketing. We simply use the best materials for each specific design requirement and rigorously check every single square inch of imported material that comes into the factory before production.

We have an entire factory department dedicated to this quality control inspection process, returning any imperfect sections that are supplied, which is another reason why the finish on our final products borders on perfect.

Ultra-X materials are a culmination of all that we've learnt through more than two decades of running our own factory that builds paragliders, wingsuits, kites, wings and accessories. In collaboration with colleagues in the dedicated prototyping department, our design team embarked on an intense material development and testing programme spanning more than three years.

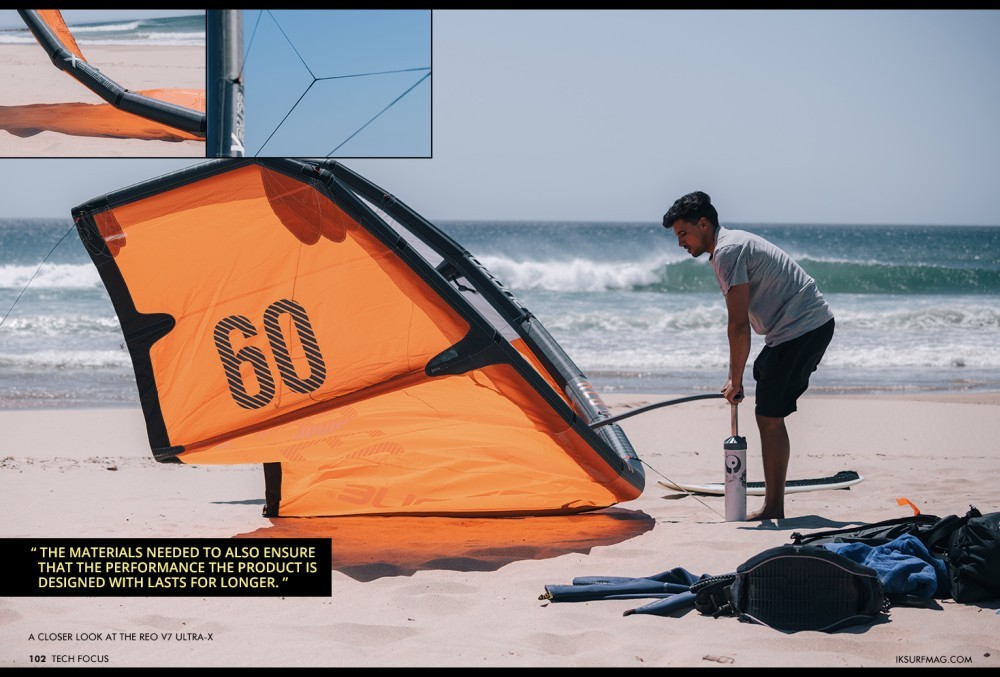

We were searching for new canopy and leading edge/strut materials with an optimum strength-to-weight ratio. Not only that; the materials needed to also ensure that the performance the product is designed with lasts for longer.

'Ultra-X' is not just one type of material for the canopy and one for the leading edge and struts. For the canopy, we are currently using the latest 46g double ripstop Teijin cloth that is 17% lighter than a 55g standard triple ripstop.

For the leading edge and struts, we are using a 125g performance Dacron that's 20% lighter than conventional Dacron and is also more rigid. We've also done a lot of prototyping over the years with Aluula. It's not just about implementing a product like that. Understanding how materials work together is vital. As Aluula materials have developed, we are now looking forward to incorporating it into new products coming in 2024.

The bridles also got the Ultra-X update! Can you tell us more about the bridle lines and how they have changed?

That's right; we worked on every detail down to the type of line and thickness for the bridles. On the Ultra-X range, we are using both high-performance Technora and/or sheathed Dyneema line materials, which offer a vast reduction in parasitic drag and reduced weight.

The Ultra-X range has been developed with high performance in mind. When flying an Ozone Reo next to a Reo Ultra-X, what performance or flying characteristics are different?

Using lighter-weight materials translates to true performance increases - the kites fly faster and are more reactive, even in the lightest breeze.

The Reo V7 is already a high-performance wave kite and is close to being as light (or lighter) as some competitors' light weight kites. The Reo V7 Ultra-X takes it to the next level. You will notice even more drift, increased response time, better upwards drive and tighter loops. Essentially, it's extremely reliable when you need it most in any wave conditions, anywhere in the window.

Would you recommend a beginner kiteboarder to choose an Ultra-X model or a standard model? Why?

In general, we wouldn't recommend a beginner kiteboarder to choose an Ultra-X model. The materials were chosen because they're stiffer and often stronger for the intended use; however, like a carbon fibre road bike, the Ultra-X materials require an appreciation for how to handle high-performance gear.

If you regularly kite off a rocky or sharp shell beach, or are often crashing your kite, the thicker materials of a standard model will provide more 'scuffable' material with the extra layers of fibre for longer lasting wear and tear abuse.

Will other kites in the Ozone range get an Ultra-X upgrade? Are there any that won't, and what would the reason for that be?

Yes, there will be more Ultra-X kite models to come in the Ozone range. These will be our specific models in particular performance categories.

There are some models that won't be produced with Ultra-X materials. The main reason for that being those models are entry level to intermediate progression kites, where the customer wouldn't really benefit as much from higher priced, higher performance materials.

We also suggest that if, for example, you often wave kite in storm force conditions, then the robust wear and tear nature of the standard Reo V7 in the small sizes will be of more benefit, with the stronger winds also reducing the need for such light weight handling benefits.

Because Ozone is one of the few brands with their own factory, how does this impact testing and producing with new, light weight materials?

When it comes to testing and producing with new materials, we are incredibly proud to own and operate our own factory, where a thousand highly trained employees apply their skills across nine factory floors, including the dedicated prototyping department that operates full time.

The turnaround on material lab tests through to implementing chosen materials into physical products is super fast. Our designers capitalise on having 100% access to the factory to try new ideas, producing as many prototypes as it takes to make products feel just right.

While we own all production processes in the factory, we also own these processes in design. Our highly advanced, custom-built OzCAD software, built from the ground up, means that our designers intimately understand every square inch of pressure exerted into various materials.

Is sustainability a priority for Ozone and your product range?

Sustainability is a huge priority for Ozone, and it's always been evident, but not just in the most obviously publicised ways used in marketing. Sustainability is a practice and an ever-evolving journey. It runs through everything we do, from the solar panels on the roofs of all nine of our factory units to the custom-built CNC machines and nesting programme that ensures we cut each piece of material with minimum waste. Our clutchless sewing machines also use less power, and we use material offcuts to make bags, straps or panels for harnesses, for example.

Even the cardboard used for our shipping boxes is cut and shaped to reduce waste and ensure that we are only transporting products, not just air.

We believe that another aspect of Ozone's approach that makes us different is our lean manufacturing approach. We not only offer ever-improving levels of sustainability, but also a fairer and more transparent business model for our distributors, retailers and end customers.

We do not produce in large batches; all products are manufactured to order using our bespoke B2B ordering system. This method of production is unique to the kitesurf industry and means there is no extra stock flooding into the market, which can devalue a product at the end of the season.

We don't release new versions of each model every year; instead products are set free onto the market once all designers and the R&D team agree that big improvements have been made.

We have adopted this approach to avoid confusion in model updates; this also gives our design team time for true innovation. We strive to be transparent in our innovation – this is good news for customers, as the performance of a new version will be an improvement, and the value of the existing version will remain higher for longer.

Once a product is signed off by the team, there is very little lag time between that moment and the product then being released publicly. All equipment that comes out of the factory is made to order, so there are no big warehouses of pre-made stock sitting idle for months that need storing before then needing to be pushed to market to make space for yet another new product to take its place.

Ozone delivers products within 15 – 30 days after the order is placed on our B2B ordering system, allowing shops to carry just the right amount of gear they need to sell over the coming month. Once a new product is signed off, it can be in a customer's hands just a month later.

Will we see more recycled materials entering the kite industry in the future? What are your thoughts on the future of kite development?

You will. We have been working in collaboration with Patagonia to make this a reality in kiteboarding products, specifically relating to kite canopy materials. You'll have to wait a little longer to hear more on that, but you can read more about the collaboration and our goals to benefit the industry by clicking here.

Videos

By Crystal Veness

Editor at IKSURFMAG, Crystal Veness hails from Canada but is based in South Africa. When she isn't busy kitesurfing or reporting on the latest industry news for the mag, she is kicking back somewhere at a windy kite beach or working on creative media projects.