Tech Focus: ION Max_Flex

Issue 100 / Wed 9th Aug, 2023

It's not just kites that are getting the innovative materials treatment; neoprene accessories are going through a major development period, too! At ION's in-house laboratory, they've developed an ultra-stretchy wetsuit lining called Max_Flex. Find out what's outside ION's wetsuits in this interview with Michi Schuster!

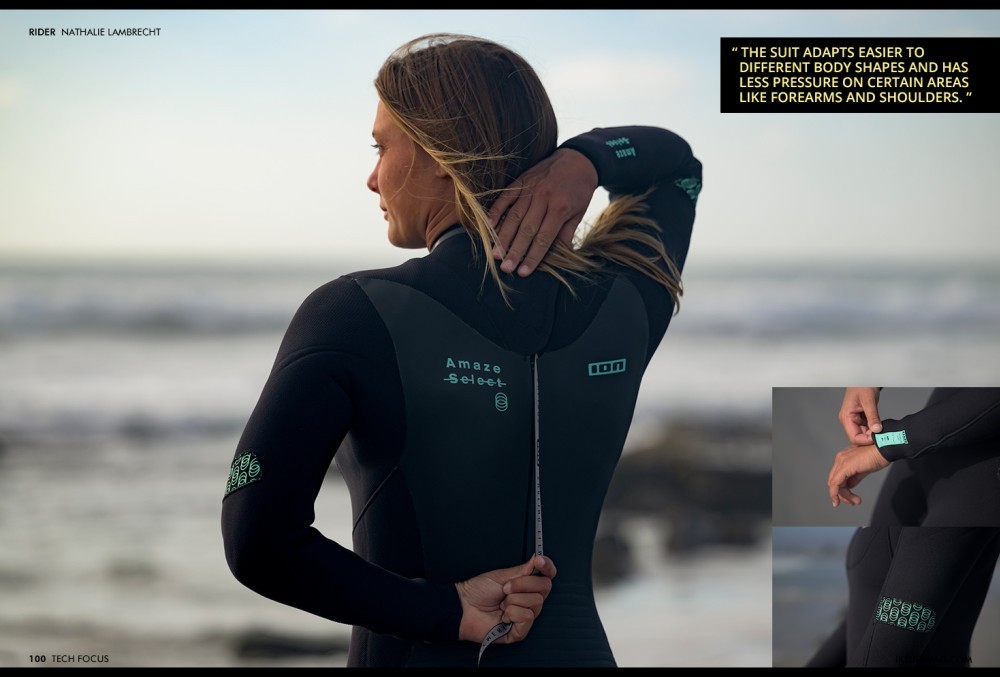

Tell us more about the Max_Flex outer lining! What makes it so stretchy?

The unique weaving structure and the combination of the materials make this material so stretchy. The rhombus-shaped structure elongates without much power needed once force is applied. Furthermore, the structure helps to reduce pressure on specific areas of the body because of its 3-dimensional stretch.

Featured on the premium Select and Amp ranges, how does the flexibility of Max_Flex material compare to the neoprene in the Core range?

The direct comparison must be made with the lining only since a wetsuit's lining is the key factor in this case for stretch improvement. Compared to standard linings in the market, ION Max_Flex needs 30% less force for the same amount of stretch. That means the suit adapts easier to different body shapes and has less pressure on certain areas like forearms and shoulders. All of this makes the general fit significantly more comfortable.

Are there additional features outside of more stretch and flexibility that users might notice?

Our Max_Flex material has quite a big surface because of its 3D-weaved structure. This means that the water is getting distributed throughout the whole surface through small channels. This allows the water to evaporate quicker, hence reducing the drying time.

What went into developing the Max_Flex outer lining? How does one discover or create a material like this?

We invested heavily in our in-house laboratory during the last couple of years. This enabled us to test and develop this material at a fast pace, and we could quickly test the differences between all the different materials.

Can you share some insight into the production process? Where does ION produce this material?

All our wetsuits are produced in the world's leading factory for wetsuits. And luckily, our production partner takes development very seriously. Therefore, everything is getting developed and produced in-house. This allows them to meet the specific needs of our development goals and turn them around in a short time frame. At the same time, the production partner stands out by integrity, ensuring R&D secrecy between the brands producing in the same spot.

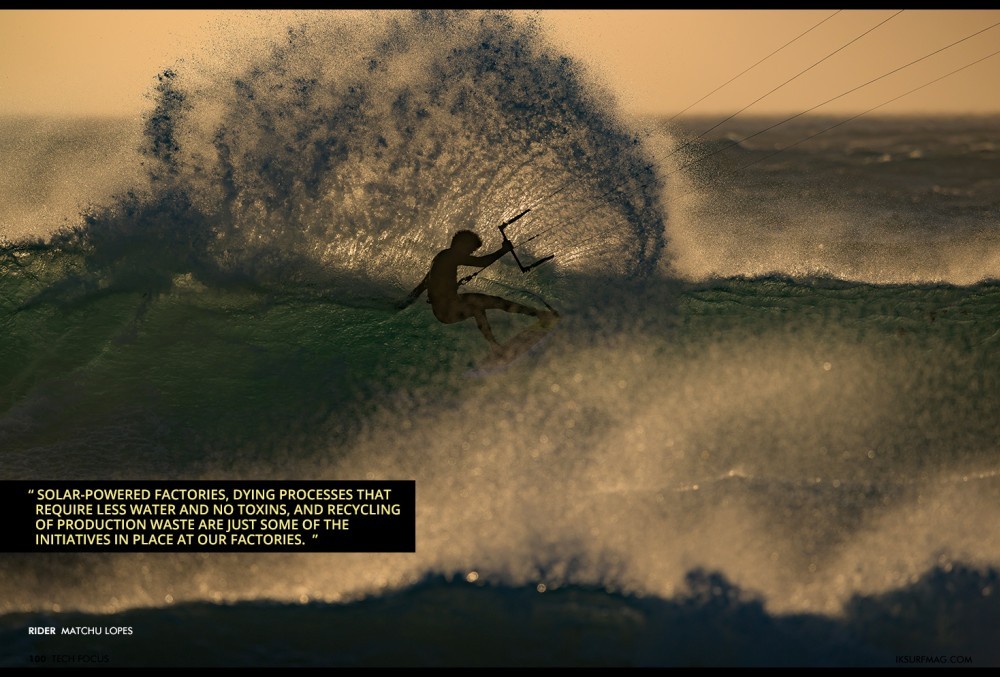

What sustainability initiatives does ION incorporate into their production?

Sustainability awareness starts with the selection of materials. As different materials are used, sustainable initiatives vary by product. Max_Flex featuring wetsuits are made partially from Japanese-sourced limestone neoprene replacing petrochemicals in the neoprene. To enhance the sustainable contribution, we mix in bio-calcium oxide powder from abandoned waste shells and Eco-Carbon Black, which is pyrolyzed from scrap rubber tires.

The factory that we work with is not only the world's leading wetsuit factory but, more importantly, the leading wetsuit producer regarding sustainability. Solar-powered factories, dying processes that require less water and no toxins, and recycling of production waste are just some of the initiatives in place at our factories. They are constantly improving and challenging the market, similar to ION.

To further reduce a wetsuit's ecological footprint, we have compensated for the CO2 emissions created during the production process and the shipment by partnering with Climate Partner for a couple of years.

Can you share any other details or last words about Max_Flex with us?

I want to point out that Max_Flex is not only featured in the Select and Amp level wetsuits. We also integrated Max_Flex into the footwear range, some neoprene tops, and impact vests. Just try it! It's a game-changer in many aspects.

By Crystal Veness

Editor at IKSURFMAG, Crystal Veness hails from Canada but is based in South Africa. When she isn't busy kitesurfing or reporting on the latest industry news for the mag, she is kicking back somewhere at a windy kite beach or working on creative media projects.